IN THIS ARTICLE

This is why you should stay away from Amateur warehouse floor contractors

If you manage or own a warehouse, you already know your concrete floor takes a beating every single day. Forklifts are constantly moving. Pallet jacks roll back and forth. Racks are loaded with heavy inventory. People are on their feet all day trying to get work done safely and efficiently.

When concrete floor damage shows up, cracks, spalling, broken joints, uneven slabs, dusting surfaces, the pressure is on to fix it fast. That is often where mistakes happen. It is tempting to hire the cheapest contractor or someone who says they can patch it quickly. On the surface, it may look like a smart way to save money.

In reality, hiring an amateur or inexperienced warehouse floor repair contractor often ends up costing more in the long run. We see it all the time. We are called in after a failed repair to redo work that should have been done correctly the first time.

In this article, we will walk you through why warehouse concrete floor repair is not a place to cut corners, what goes wrong when amateurs handle industrial floors, and why working with a professional concrete repair contractor saves time, money, and stress over the life of your facility.

Warehouse Concrete Floors Are Not the Same as Residential or Light Commercial Floors

One of the biggest misunderstandings we see is the assumption that concrete is concrete. Many contractors who work on driveways, patios, or small commercial spaces think they can easily handle warehouse floors. The reality is very different.

Warehouse concrete floors are engineered to handle extreme conditions, including:

- Continuous forklift traffic

- Heavy static loads from pallet racking

- Impact from dropped pallets or materials

- Abrasion from hard wheels and equipment

- Temperature changes from loading docks and doors

- Moisture exposure in certain environments

Because of this, warehouse floors are typically thicker, reinforced differently, and designed with control joints, expansion joints, and flatness requirements that go beyond standard concrete work.

Repairing these floors correctly requires a clear understanding of load transfer, joint behavior, material strength, and cure times. Amateur contractors often lack this knowledge, and that gap leads directly to premature failures.

The Hidden Costs of Hiring Amateur Warehouse Floor Repair Contractors

At first glance, an amateur contractor’s price can look appealing. Lower labor rates and quick promises can make it seem like a good deal. The problem is that the true cost rarely shows up right away.

Subpar Materials That Fail Under Real Warehouse Conditions

One of the most common issues with amateur repairs is the use of the wrong materials. Industrial warehouse floors require high strength repair mortars, joint fillers, and bonding agents designed for heavy traffic and load transfer.

Amateurs often use:

- General purpose concrete patch products

- Low strength mortars not rated for forklift traffic

- Materials without proper abrasion resistance

- Products with cure times that are ignored or rushed

These materials might look fine at first, but once forklifts are back on the floor, the repairs start breaking down. Edges chip. Joints crumble. Patches pop loose.

When that happens, you are paying twice. Once for the original repair and again for the professional repair that fixes it correctly.

Improper Surface Preparation

Concrete repair is only as good as the surface preparation. This is another area where amateur work falls short.

Proper warehouse floor repair often includes:

- Mechanical grinding or milling

- Removal of weak or contaminated concrete

- Cleaning and profiling the surface

- Proper priming or bonding agents

Skipping or rushing these steps saves time upfront but leads to poor adhesion and early failure. The repair material never truly bonds with the existing slab.

We often see repairs that look like they were simply poured or troweled over damaged areas without proper prep. Those repairs rarely last.

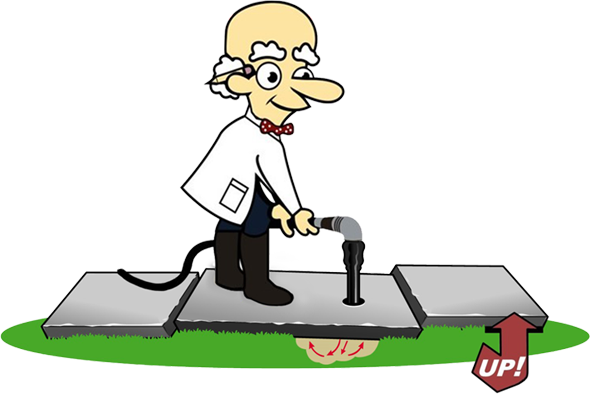

Ignoring Joint and Load Transfer Issues

Joints are one of the most critical parts of a warehouse floor. They allow the slab to move while maintaining load transfer between panels. When joints break down, forklift wheels take repeated impact, which accelerates damage.

Amateurs often ignore joint design entirely. They may fill joints incorrectly, use rigid materials where flexible ones are needed, or leave joints untreated after patching.

This leads to:

- Joint edge spalling

- Increased vibration for forklifts

- Damage to lift equipment

- Safety concerns for operators

A professional understands how joints function and how to repair them in a way that restores performance, not just appearance.

Operational Disruptions Cost More Than You Think

Downtime is expensive in a warehouse. Missed shipments, delayed picking, and disrupted workflows all impact your bottom line.

Amateur contractors often underestimate how critical scheduling and coordination are in an active facility. Common problems include:

- Repairs taking longer than promised

- Areas reopened before materials are fully cured

- Poor communication with warehouse staff

- No plan to work around operations

We approach warehouse floor repairs with your operations in mind. Cure times, traffic patterns, and safety zones are all planned before work begins. That planning minimizes disruption and keeps your business moving.

When amateur repairs fail or drag on, the cost is not just the repair itself. It is the operational headache that comes with it.

Safety and Liability Risks You Cannot Ignore

Damaged concrete floors are more than a maintenance issue. They are a safety risk.

Uneven surfaces, broken joints, and spalled areas increase the risk of:

- Trips and falls

- Forklift instability

- Load shifting or tipping

- Equipment damage

If an amateur repair creates or fails to fix these hazards, your exposure to liability increases. In many cases, facility managers do not realize how risky a poorly repaired floor can be until an incident occurs.

Professional concrete repair focuses on restoring flatness, strength, and durability so your floor supports safe daily operations.

What Professional Warehouse Concrete Floor Repair Really Involves

Hiring a professional contractor is not just about paying more for labor. It is about investing in a process that delivers long term performance.

Experience and Product Knowledge

Professional warehouse floor repair contractors have spent years learning how different products perform under real world conditions. We understand:

- Which materials work best for forklift traffic

- How cure times affect reopening schedules

- How temperature and moisture impact repairs

- How different floor issues interact with each other

This knowledge allows us to select the right solution for your specific problem instead of applying a one size fits all patch.

Correct Repair Methods for Long Term Durability

Every warehouse floor issue has a root cause. Cracks, spalling, and uneven slabs do not happen randomly.

Professional repair addresses the cause, not just the symptom. That may include:

- Rebuilding damaged joint edges

- Using high strength repair mortars

- Properly sealing and protecting joints

- Leveling uneven slabs where needed

The goal is not a quick cosmetic fix. The goal is a repair that holds up under daily use.

Efficient Project Management

We know that minimizing disruption is a top concern for warehouse operators. That is why professional contractors focus heavily on planning.

Before repairs begin, we work with you to:

- Identify priority areas

- Schedule work around operations

- Plan traffic control and safety zones

- Set realistic timelines

This approach keeps your facility running while repairs are completed correctly.

Ongoing Support and Accountability Matter

One major difference between professional and amateur contractors is accountability.

Reputable warehouse concrete repair contractors stand behind their work. If an issue arises, there is a clear point of contact and a commitment to make it right.

Amateurs often disappear after the job is done. When repairs fail, you are left searching for another contractor and paying again.

Support and accountability provide peace of mind that your investment is protected.

The Real Cost Comparison Over Time

It is easy to compare repair quotes line by line. It is harder, but more important, to compare long term cost.

Amateur repairs often lead to:

- Shorter service life

- Frequent re repairs

- Increased equipment wear

- Higher safety risk

- More downtime

Professional repairs cost more upfront but reduce these ongoing expenses. Over the life of your warehouse floor, that difference adds up quickly.

In most cases, the professional option is the more cost effective choice when you look beyond the initial invoice.

Signs Your Warehouse Floor Needs Professional Attention

If you are seeing any of the following issues, it is time to involve a professional concrete repair contractor:

- Cracks that keep reopening

- Spalling around joints

- Uneven or sunken slabs

- Dusting or surface breakdown

- Increased forklift vibration

- Repaired areas failing repeatedly

Ignoring these signs or relying on temporary fixes often makes the problem worse and more expensive to solve later.

What We Offer

We focus exclusively on warehouse concrete floor repair. This is not a side service for us. It is what we do every day with over 25 years of experience in the industry..

Quality

We provide concrete floor repairs built to handle the daily stress of warehouse environments. Our repairs are designed to endure forklift traffic, heavy loads, and continuous use.

Experience

We bring extensive product knowledge to every project. We use high quality repair materials and follow manufacturer recommended installation methods. We understand how these products perform in real warehouse conditions.

Price

Our pricing is accurate and realistic. It allows us to do the job right, maintain an experienced crew, and support your facility long term. We do not cut corners to win jobs.

Service

We know minimizing disruption to your daily operations is critical. We work with you to create a repair plan before work begins so expectations are clear and downtime is limited.

Results

Our focus is on long lasting repairs, improved safety, compliance, and real cost savings over time.

Our Service Area

We specialize in warehouse concrete floor repair in:

- New Jersey

- Eastern Pennsylvania

- Lehigh Valley

- Northampton County

- Lehigh County

- Bucks County

- Montgomery County

- Philadelphia County

Conclusion

Your warehouse floor is a critical part of your operation. When it starts to fail, the choice you make about who repairs it matters more than you might think. Hiring an amateur may seem like a way to save money, but the hidden costs of poor materials, improper techniques, downtime, and repeat repairs quickly outweigh any short-term savings.

Professional warehouse concrete floor repair is an investment in safety, efficiency, and long-term performance. It keeps your operation moving and protects your bottom line.

If you manage a warehouse in New Jersey or Eastern Pennsylvania and are dealing with concrete floor damage, we are here to help.

Contact us today to discuss your warehouse concrete floor repair needs. We will take the time to understand your facility, explain your options clearly, and put together a repair plan that works for your operation.

When you are ready to fix it right the first time, we are ready to get to work.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025