OUR SERVICES

CONCRETE SPALLING REPAIR

Concrete floors in industrial warehouses are essential for the efficient functioning of operations. However, the frequent occurrence of concrete spalling poses a significant challenge, jeopardizing the integrity and safety of these essential surfaces. Dealing with spalling, which occurs when concrete chips, flakes, or breaks off, requires specific repair methods designed for the specific requirements of warehouse settings.

Implementing targeted strategies is vital to mitigate risks, prevent further deterioration, and ensure the long-term durability of warehouse flooring.

Understanding Concrete Spalling: While outdoor concrete spalling is often induced by factors such as freeze-thaw cycles or inadequate curing, indoor industrial concrete floor surface failures are often caused by forklift traffic or chemical exposure. This can lead to the degradation of the concrete surface and compromise the structural stability of the warehouse floor. The deterioration typically begins with the formation of small cracks and eventually progresses to the detachment of concrete fragments, leaving behind uneven and hazardous surfaces.

Recognizing the underlying causes and early signs of spalling is crucial to implementing timely and effective repair measures.

Importance of Swift Spalling Repair:

Neglecting spalling concrete can exacerbate the problem, resulting in increased safety hazards and potentially impacting the functionality of warehouse operations. Uneven surfaces and loose debris can impede the movement of material handling equipment and pose risks to the safety of workers. Prompt repair prevents further damage and contributes to maintaining a secure and efficient working environment, ensuring uninterrupted logistical activities.

Specialized Repair Techniques for Spalling Concrete:

- 1

Concrete Patching: Utilizing high-quality epoxy mortar compounds to fill and repair surface spalling, restoring the structural integrity and smoothness of the concrete floor.

- 2

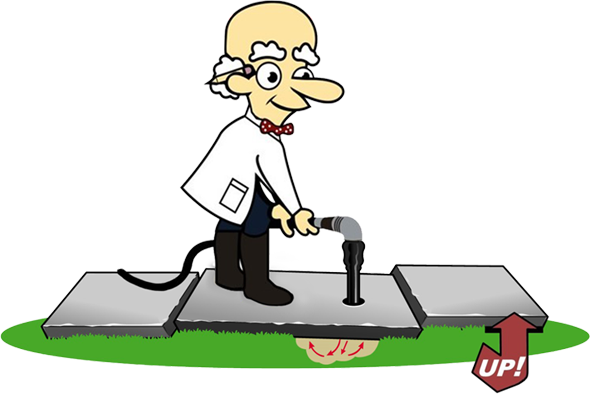

Surface Preparation: Thoroughly cleaning and preparing the damaged areas through techniques such as shot blasting or grinding to facilitate strong adhesion of repair materials.

- 3

Epoxy Injection: Injecting epoxy resins into the concrete fissures to seal and reinforce the cracks, preventing moisture intrusion and further spalling.

- 4

Overlay Systems: Applying chemically engineered overlay systems to resurface and strengthen the concrete, enhancing its resistance to abrasion, impacts, and chemical exposure.

Working with skilled professionals is important when repairing damaged concrete floors in warehouses. They should have extensive knowledge in restoring industrial flooring. These qualified specialists are able to thoroughly evaluate the situation, suggest customized repair options, and carry out the necessary fixes with accuracy, following industry regulations and optimal techniques. Their expertise guarantees the implementation of resilient and enduring repairs, effectively protecting the warehouse floor from further deterioration and potential hazards.

Conclusion:

It is important to keep concrete floors in warehouses safe and in good condition for smooth daily operations. By recognizing the significance of timely repairs, employing specialized repair techniques, and collaborating with our seasoned professionals at Concrete Chiropractor, warehouse owners and managers can uphold the resilience and longevity of their concrete floors. It is crucial to give priority to preventive maintenance and specific repairs to maintain the strength and stability of warehouse floors. This will create a safe and suitable environment for smooth logistical operations.