IN THIS ARTICLE

DIY Concrete Floor Gouge Repair: All you need to know

So, can you repair concrete floor gouges yourself?

The answer is yes, if you have costly and proper equipment along with the knowledge. However, it typically never lasts and requires professional repair. Some concrete floor gouges can be fixed yourself—but only in limited situations. Very small, shallow surface gouges that do not affect the strength or flatness of the slab can sometimes be repaired with basic patching materials. However, most gouges found on warehouse concrete floors are not ideal candidates for DIY repair, especially in active industrial environments.

In warehouses, concrete floors are subjected to constant forklift traffic, pallet jacks, racking systems, and heavy point loads. What may look like a simple gouge on the surface is often a sign of deeper wear, weakened concrete, or poor bonding beneath the top layer. In those cases, a DIY repair may temporarily hide the damage but will usually fail under continued use.

This article explains when DIY repair is realistic, when it is not, and what warehouse owners and facility managers in New Jersey and Eastern Pennsylvania should realistically expect when dealing with concrete floor gouges.

What Are Concrete Floor Gouges?

Concrete floor gouges are localized sections of missing or damaged concrete, typically caused by mechanical impact or abrasion. Unlike hairline cracks or surface dusting, gouges involve a noticeable loss of material.

In warehouse environments, gouges most often develop from forklift forks scraping the floor, steel wheels turning under load, dropped pallets, or racking systems being dragged instead of lifted. Over time, repeated traffic concentrates stress in the same areas, leading to surface failure.

A gouge may start shallow, but once the top layer of concrete is compromised, it becomes more vulnerable to further damage. Moisture intrusion, fine debris, and continued impact can cause the gouge to grow wider and deeper.

From an operational standpoint, gouges are more than a cosmetic issue. They can interfere with pallet movement, create vibration for forklifts, and contribute to uneven floor conditions. In regulated environments, they can also raise safety concerns.

Can You Realistically Repair Concrete Floor Gouges Yourself?

Whether a gouge can be repaired by a warehouse operator or maintenance team depends largely on depth, size, location, and floor usage.

For very small gouges—typically shallow surface damage less than a quarter inch deep and located in low-traffic areas—DIY repair may be possible. These repairs usually involve cleaning the damaged area, applying a concrete patch or epoxy filler, and allowing it to cure fully before reopening the area to traffic.

However, this is where expectations must be realistic. DIY repairs are surface-level solutions, not structural repairs. They may restore appearance temporarily, but often do not restore the original strength or durability of the slab.

In high-traffic warehouse zones such as loading docks, main forklift aisles, staging areas, or racking rows, DIY repairs are rarely successful in the long term. The repaired area is exposed to constant abrasion and heavy loads, which quickly reveal weaknesses in bonding or curing.

Another challenge with DIY repairs is floor flatness. Warehouses often require level floors for safe material handling. Improper patching can leave high spots or depressions that make the problem worse rather than better.

Why DIY Repairs Often Fail on Warehouse Floors

DIY concrete repairs commonly fail in warehouse settings for a few key reasons.

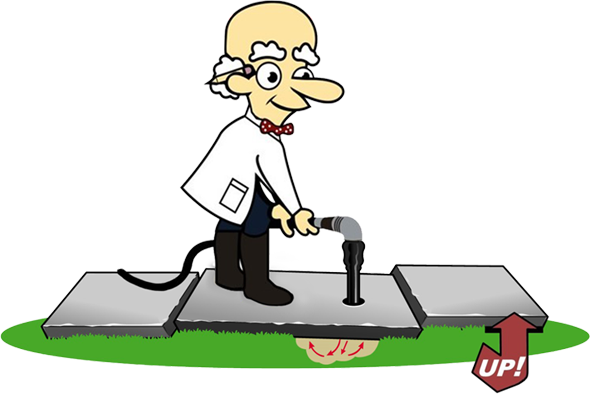

First, surface preparation is usually inadequate. Industrial concrete repair requires grinding or profiling the surface to ensure proper bonding. Simply cleaning a gouge with a broom or pressure washer is rarely enough.

Second, most off-the-shelf repair products are not designed for continuous forklift traffic. They may cure hard, but they lack the compressive strength and abrasion resistance needed for industrial use.

Third, curing conditions matter more than many people realize. Temperature, humidity, and floor moisture content all affect how well a repair bonds. Warehouses rarely provide ideal curing conditions without specialized planning.

Finally, the underlying issue that caused the gouge—such as joint failure, poor original finishing, or load concentration—often goes unaddressed. Without correcting the root cause, the damage simply returns.

When Concrete Floor Gouges Require Professional Repair

If a gouge is deeper than the surface layer, located in a high-traffic area, or recurring in the same spot, professional repair is the more practical option.

Professional concrete floor repair involves more than filling a hole. It begins with a proper evaluation of the slab condition, traffic patterns, and load requirements. The damaged area is mechanically prepared, repaired using industrial-grade materials, and finished to blend with the surrounding floor.

In warehouse environments, professional repairs are designed to restore both durability and functionality, not just appearance. This is particularly important where forklifts, automated equipment, or high stacking systems are involved.

For facilities in New Jersey and Eastern Pennsylvania, professional repair also helps ensure compliance with safety standards and reduces the risk of operational downtime caused by repeated patch failures.

Common Professional Repair Methods for Gouged Warehouse Floors

Professional repairs vary depending on the severity of the gouge and the condition of the surrounding concrete.

Shallow gouges may be repaired using high-strength epoxy or polymer-modified mortar systems. These materials bond aggressively to the existing slab and are formulated to withstand heavy traffic.

Deeper gouges may require partial depth repair, where damaged concrete is removed to a sound substrate before new material is installed. This approach restores structural integrity and prevents future delamination.

In some cases, grinding and leveling are used to correct uneven areas after repair, ensuring smooth forklift travel. Where widespread surface damage exists, localized resurfacing may be recommended to improve durability across a larger area.

Each method is selected based on the specific demands of the warehouse floor, not a one-size-fits-all approach.

Cost Considerations: DIY vs Professional Repair

Cost is often the main reason warehouse operators consider DIY repairs. On the surface, buying patching material appears cheaper than hiring a professional.

DIY costs are generally limited to materials and labor time. However, repeated failures, reapplication, and potential operational disruptions often increase long-term costs.

Professional repairs involve a higher upfront expense, but they are designed to last significantly longer. A properly executed repair reduces repeat maintenance, minimizes downtime, and protects equipment from unnecessary wear caused by uneven flooring.

When evaluating cost, it is important to consider total lifecycle cost, not just the initial repair expense.

Concrete Floor Gouges and Warehouse Safety

Gouged concrete floors can pose safety risks, particularly in fast-moving warehouse environments. Uneven surfaces can cause forklift instability, pallet shifting, and operator fatigue. For pedestrian areas, gouges increase trip hazards.

In regulated industries, damaged flooring may also raise compliance issues. Addressing gouges promptly and correctly helps maintain a safer working environment and reduces liability exposure.

Professional repairs are typically completed with safety and operational continuity in mind, often staged to minimize disruption to warehouse activity.

Preventing Concrete Floor Gouges in Warehouses

While not all damage can be avoided, several measures help reduce the frequency and severity of gouges.

Proper forklift operation and training play a major role. Avoiding dragging forks, managing turning speeds, and maintaining equipment all help protect the floor surface.

Regular floor inspections allow small issues to be addressed before they worsen. Early intervention is often far less disruptive and costly than reactive repair.

In high-impact zones, protective coatings or reinforced repair materials may be used to improve resistance to abrasion and impact over time.

Warehouse Concrete Floor Repair in New Jersey and Eastern Pennsylvania

We specialize exclusively in warehouse concrete floor repair in New Jersey and the eastern part of Pennsylvania, including the Lehigh Valley, Northampton County, Lehigh County, Bucks County, Montgomery County, and Philadelphia County.

Our focus is on practical, durable solutions for active warehouse environments. We understand the demands placed on industrial floors and the importance of minimizing downtime.

Whether you are dealing with isolated gouges, recurring surface damage, or widespread floor deterioration, we assess the condition of your floor and recommend repairs that match your operational needs.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025