IN THIS ARTICLE

Learn What to Do When Your Industrial Concrete Floors Crack

No one wants to discover cracks in their freshly installed concrete floors, yet it happens frequently, especially in industrial settings like warehouses. Cracks can affect not only the structural integrity but also the aesthetic appeal of the flooring.

When addressing these issues, it’s crucial to understand the cause, the severity of the cracks, and the best approach to repair them. Immediate action is often required to prevent further damage or costly floor replacement.

It’s important to remember that not all cracks indicate a severe underlying issue; however, any visible cracking should be assessed by professionals to ensure safety and longevity. Our expert warehouse floor repair services can provide an accurate diagnosis and suggest appropriate repairs or maintenance. Consulting professionals can help you with efficient repair services, ensuring your warehouse floor returns to its optimal state.

Five Common Causes of Concrete Floor Cracks in Warehouses

Improper Installation Techniques

Improper installation techniques are a leading cause of cracks in concrete warehouse floors. When installation is rushed or lacks attention to detail, the foundation that supports your floor can quickly become compromised.

Mistakes made during the initial laying of concrete, such as inadequate curing time or using an incorrect concrete mix that doesn’t have the right proportions of cement, aggregates, and water, set the stage for future cracking and weaknesses.

Lack of Adequate Expansion Joints

The absence of adequate expansion joints is a prevalent cause of cracks in concrete floors. Expansion joints are crucial elements designed to handle the natural thermal expansion and contraction of concrete due to temperature changes and moisture variations.

Without these joints, concrete floors have insufficient space to accommodate such movements, leading to increased internal stresses. Concrete, while highly effective in compression, can be weak in tension, making the presence of expansion joints vital to prevent excessive stress. The width of these joints is carefully calculated to balance the floor’s structural integrity and minimize the occurrence of cracks.

Rapid Drying and Temperature Fluctuations

Rapid drying and temperature fluctuations are significant contributors to cracks in concrete warehouse floors. When concrete dries too quickly, it often lacks the proper moisture needed for full curing, leading to contraction cracks due to insufficient contraction joints.

The swift evaporation of surface water, particularly in high-temperature, low-humidity environments, can lead to uneven shrinking, known as shrinkage cracks. Additionally, crazing can occur as fine, random surface cracks when the top layer shrinks. These cracks manifest shortly after the concrete is poured as the surface layer tightens prematurely.

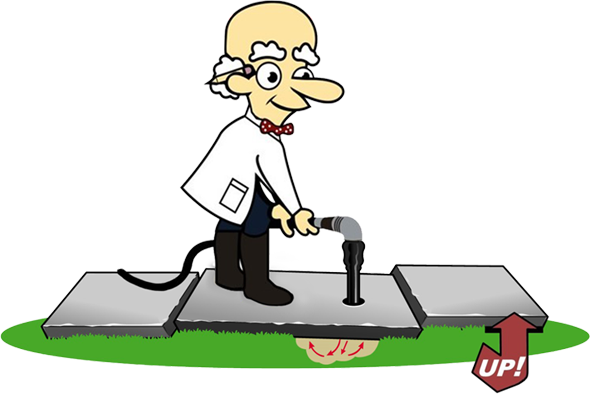

Structural Movement and Settlement

Structural movement and settlement are among the most concerning causes of cracks in concrete warehouse floors. These issues typically arise when the foundation underlying a concrete slab experiences shifts due to variations in the soil composition or environmental conditions.

Whether due to the natural settling of newly compacted earth, changes in soil moisture levels, or the decomposition of organic materials, these movements create stress and strain in the concrete. Settlement cracks are particularly common in areas where the ground beneath the structure has not been adequately prepared or compacted before construction.

Such cracks may develop vertically or diagonally, indicating that the foundation is settling unevenly. They often begin small but can widen and multiply if not addressed, posing a risk to the floor’s overall stability. Coupled with voids that may form beneath the slab, the presence of such cracks can exacerbate structural instability.

Water and Chemical Infiltration

Water and chemical infiltration are significant factors that can lead to cracks in concrete warehouse floors. Concrete is inherently porous, allowing water and chemicals to penetrate its surface and seep into its core. This infiltration often leads to internal stress, corrosion of the reinforcement, and subsequent cracking. When water enters the concrete, especially in regions with freezing temperatures, it can freeze and expand, causing the cracks to worsen as the ice amplifies the gaps.

Chemical infiltration, such as exposure to oils, acids, or alkalis, commonly encountered in industrial settings, can weaken the concrete matrix. These chemicals can alter the pH balance, leading to deterioration and compromising the structural integrity. Over time, this results in the degradation of the concrete and the appearance of cracks. Continuous abrasion from small, hard-wheeled traffic and design flaws can exacerbate these issues.

When to worry about cracks in concrete floors?

Not all cracks in concrete floors require immediate action; however, certain signs indicate when you should be concerned. It’s crucial to assess cracks based on their size, location, and pattern. Small hairline cracks are usually cosmetic and not a cause for major concern. However, if the cracks grow larger over time or if multiple cracks appear, this might indicate structural issues that need addressing.

Worry is warranted when cracks are wider than a quarter-inch or when they form in a zigzag pattern. These cracks suggest potential underlying problems such as excessive settling or poor installation. Cracks located near load-bearing areas or across expansion joints may compromise the structural integrity of the floor, requiring prompt attention.

Additionally, any cracks that allow water to seep through should be investigated, as water infiltration can lead to further damage and even reinforcement corrosion. Operational impacts, such as difficulty in equipment mobility over the cracks, also signal the need for repair.

Prevention Tips to Avoid Concrete Cracks

Regular Maintenance

Regular maintenance is a cornerstone in preventing cracks in concrete warehouse floors. This proactive approach mitigates wear and tear, catching potential issues before they become significant problems.

Regular inspections are your first line of defense in spotting early signs of distress, such as small cracks or areas where the finish is wearing thin. By addressing these early indicators, you can prevent small imperfections from escalating into major structural concerns.

Develop a routine inspection schedule, aiming for at least annual inspections. Adjust for high-traffic areas, which may require quarterly checks. During these inspections, focus on high-stress zones where machinery operates or heavy items are stored. If you notice minor cracks or surface irregularities, employ quick repair solutions, such as patching or applying sealants, to hinder further deterioration.

Hire a Professional Warehouse Concrete Floor Expert

Hiring a professional warehouse concrete floor expert is a critical step in effectively maintaining and repairing concrete floors. Professionals bring a wealth of experience and technical expertise that can be invaluable in assessing the condition of concrete floors, diagnosing underlying issues, and implementing the most suitable repair and maintenance strategies.

They can accurately identify problematic areas that might be overlooked by untrained eyes, ensuring that minor issues are addressed before they develop into more severe, costly problems.

At Warehouse Concrete Floor Repair, we specialize in expert concrete floor repair and replacement to keep your warehouse floors strong, safe, and functional. If your concrete floor is damaged, addressing it quickly is key to preventing further issues that could disrupt your operations.

Our team ensures all repairs meet safety and construction standards, helping you maintain a secure work environment while avoiding costly liabilities. Whether you need a minor repair or a full concrete floor replacement, we have the expertise to get the job done right. Contact us today to discuss your project and restore the strength of your warehouse floors.

FAQs

What is the most common causes of concrete floor cracks?

The most common causes of concrete floor cracks are improper installation techniques, lack of adequate expansion joints, rapid drying, temperature fluctuations, structural movement, and water or chemical infiltration. These factors can stress and pressure the concrete, resulting in cracks over time. Regular inspections and maintenance can help identify and address these issues early.

Is it necessary to repair small cracks immediately?

Yes, it’s advisable to repair small cracks immediately. While they may seem minor, small cracks can allow moisture to enter, potentially leading to more severe damage over time. Prompt repair prevents further deterioration and helps maintain the structural integrity of the concrete floor.

Are cracks in concrete garage floors normal?

Yes, cracks in concrete garage floors are normal and often result from settling, temperature changes, or shrinkage during drying. While they are common, it’s important to monitor their size and progression, as larger or expanding cracks may need professional evaluation and repair.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025