IN THIS ARTICLE

Discover some of the Common Issues with Warehouse Concrete Floors and How to Address Them

Warehouse concrete floors are not just another part of your building. They are the foundation that keeps everything in motion—forklifts, pallet jacks, storage racks, and workers on foot. When the floor is in good condition, operations flow smoothly. But when it begins to fail, even small issues can disrupt productivity, damage equipment, and compromise safety.

Industrial and food storage facilities place unique stress on concrete. Cold storage warehouses, for example, face constant temperature changes that cause the slab to expand and contract. Add in heavy forklift traffic, water from washdowns, and strict hygiene requirements, and it’s easy to see why these floors wear down faster than in other buildings.

That’s why understanding the common problems with warehouse concrete floors is so important. By spotting them early and knowing how they affect your facility, you can prevent costly downtime, maintain compliance with safety standards, and protect your equipment.

In this article, we’ll cover the most frequent warehouse floor problems, explain why they happen, and show how timely repair keeps your facility running safely and efficiently. We’ll also highlight why mudjacking is one of the most reliable and eco-friendly ways to restore damaged floors.

Common Issues with Warehouse Concrete Floors

Warehouse floors take heavy abuse every day. The constant movement of equipment, temperature shifts, and the weight of stored products all contribute to concrete deterioration. Here are the most common problems we see in warehouses across New Jersey and beyond:

- Cracks in the Slab

Cracking is one of the earliest signs of floor damage. Cracks may form from shrinkage during curing, stress from forklift loads, or expansion and contraction caused by temperature changes. While a small crack might seem harmless, it can widen over time. In food storage facilities, these cracks also become traps for dirt, water, and bacteria—creating hygiene and compliance problems. Read more about the causes of warehouse concrete floor cracks and how to fix them. - Joint Damage

The edges of concrete joints are especially vulnerable. Every time a forklift or pallet jack crosses a joint, the weight transfers onto the edges. Over time, this causes chipping, spalling, or even complete failure of the joint. Damaged joints don’t just slow down equipment; they also accelerate wear on tires and wheels. Learn about the cause of warehouse concrete floor joint damage and how to fix it. - Slab Settlement and Uneven Floors

When the soil beneath the concrete slab shifts or voids develop, parts of the floor sink. This leaves behind uneven slabs that create hazards for workers and rough rides for forklifts. Settlement also puts stress on the slab itself, causing more cracking and surface failure. - Surface Spalling and Potholes

High-traffic areas eventually lose their surface strength. Concrete may flake (spalling) or break down into potholes. This makes the floor uncomfortable to drive over, slows down workflow, and increases the risk of accidents. - Moisture Intrusion

Water is one of the most damaging elements for concrete. In warehouses with cold storage, condensation is common. Washdowns and spills add more moisture. Over time, this leads to slippery conditions, weakened concrete, and hygiene problems in food-related industries.

These issues, if ignored, don’t just affect the floor itself. They reduce efficiency, increase equipment repair costs, and create safety risks for your team. That’s why timely action is key.

How Damaged Floors Affect Warehouse Safety and Compliance

Warehouse safety is closely tied to the condition of your concrete floors. OSHA and industry-specific standards require facilities to maintain safe, hazard-free environments. When your floors are damaged, safety and compliance can quickly come under threat.

Worker Safety Risks

Trip hazards are one of the biggest concerns. Cracks, potholes, and uneven slabs can easily cause falls. Even when workers avoid accidents, navigating around damaged floors slows them down and increases fatigue. Slippery conditions from moisture make matters worse, especially in cold storage warehouses where condensation is common.

Equipment Damage and Accidents

Forklifts and pallet jacks are designed to run on flat, stable surfaces. When joints fail or floors settle, equipment jolts and vibrates with every pass. This not only damages the equipment itself but also increases the chance of dropped loads, collisions, or damaged products.

Product and Hygiene Concerns

In food storage warehouses, damaged floors present an added challenge. Cracks and pits collect dirt, debris, and bacteria that are difficult to clean. During inspections, these issues can raise red flags for compliance with FDA, USDA, or third-party safety audits. Failing an inspection can halt operations and damage your reputation.

Compliance Standards

Regulatory agencies expect facilities to maintain safe, clean, and functional floors. When you delay repairs, you increase the risk of violations and fines. Timely repair isn’t just about protecting your workforce—it also protects your business from penalties and interruptions.

The bottom line is simple: a damaged floor is not just a maintenance issue. It’s a direct threat to safety, compliance, and the smooth operation of your warehouse.

Benefits of Timely Warehouse Concrete Floor Repair

Addressing floor problems as soon as they appear is one of the smartest investments you can make for your warehouse. Timely repair delivers several important benefits:

- Accident Prevention

Small cracks and uneven slabs may seem manageable, but they often cause injuries when ignored. Fixing them right away removes hazards and helps you maintain a safer environment for workers and visitors. - Lower Maintenance Costs

Delaying repairs always makes the problem worse. A small crack might cost little to fix today, but if left alone, it can spread into a larger issue that requires slab replacement. Acting early helps avoid unnecessary expenses. - Equipment Protection

Forklifts and pallet jacks are valuable assets. Uneven floors and broken joints wear down tires, suspension systems, and load-bearing parts faster. Timely repairs protect your machines and reduce repair bills. - Regulatory Compliance

Food warehouses, cold storage facilities, and industrial plants face strict inspections. By fixing problems quickly, you show inspectors that your facility prioritizes safety and hygiene. This reduces the risk of citations and downtime. - Improved Productivity

Workers and machines move faster and more confidently across smooth floors. No one has to slow down for hazards or deal with equipment breakdowns. The result is better workflow and higher efficiency. - Longer Floor Lifespan

Concrete floors are built to last, but they still need upkeep. Timely repairs extend the life of your slab and reduce the chances of major reconstruction down the road.

Timely repair is more than maintenance—it’s an investment that pays off in safety, compliance, and long-term savings.

Mudjacking: A Reliable Solution for Warehouse Floor Repair

One of the most effective ways to fix sunken or uneven warehouse floors is mudjacking. Unlike full slab replacement, which is costly and time-consuming, mudjacking restores your existing slab by lifting it back into place.

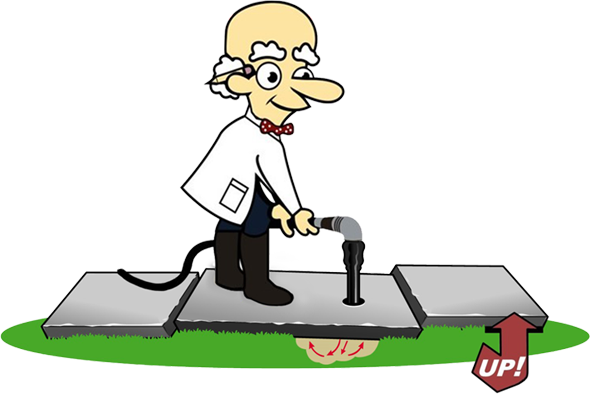

Here’s how it works:

- Small holes are drilled into the affected concrete slab.

- A cement-based slurry is pumped through the holes into the voids beneath the slab.

- The pressure of the slurry raises the slab back to its original level, stabilizing the floor.

- The holes are patched, leaving a smooth and stable surface.

Why Mudjacking Works for Warehouses

- Affordable – Mudjacking costs significantly less than replacing the entire slab.

- Eco-Friendly – The slurry is made from natural materials, making it safer for the environment.

- Durable – Once stabilized, the floor can handle heavy forklift and pallet traffic.

- Minimal Downtime – Repairs are often completed within a day, allowing warehouses to return to normal operations quickly.

- Long-Lasting Results – A properly mudjacked floor can last for many years without further issues.

For warehouses in New Jersey, mudjacking has proven to be one of the most reliable solutions. It not only restores safety but also saves money and keeps operations running smoothly.

Warehouse Concrete Floor Repair Services in New Jersey

If you are searching for warehouse concrete floor repair services in New Jersey, you need a team that understands both the technical and practical challenges of working in industrial environments. We provide professional commercial concrete floor repair across the region, focusing on cold storage and food warehouses where safety and compliance are critical.

Our repair methods, especially mudjacking, are designed to address settlement, cracks, joint damage, and potholes with long-lasting results. We know that every hour of downtime costs money, so our process is built around efficiency, safety, and minimizing disruption.

By choosing a trusted local team, you get more than just a fixed floor. You gain peace of mind knowing your warehouse is safer, more efficient, and ready for inspections. Whether you manage a food distribution center, a refrigerated warehouse, or a general industrial facility, timely floor repair ensures your operations keep moving without interruptions.

Conclusion

Warehouse floors face constant stress, and over time, problems like cracks, settlement, and joint damage are almost guaranteed. Ignoring them only leads to bigger repairs, safety risks, and compliance issues.

Timely repair is the solution. With proven methods like mudjacking, you can restore stability, protect your workers and equipment, and extend the lifespan of your floors without the high cost of replacement.

If your warehouse or cold storage facility needs reliable floor restoration, we’re here to help. Contact us today for warehouse concrete floor repair in New Jersey. Let’s keep your floors safe, strong, and inspection-ready.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025