IN THIS ARTICLE

Here is all you need to know about concrete floor repair for food storage warehouses

When you run a food storage warehouse, whether it’s for cheese, frozen goods, or packaged groceries, you know how important the floor is to your operation. The concrete beneath your feet carries forklifts, holds heavy shelving, and must stay clean enough to meet strict food safety standards. A damaged floor can slow down your team, put equipment at risk, and even create hygiene problems that no warehouse operator wants to deal with.

We’ve seen this first-hand in facilities across New Jersey. Floors that once looked solid eventually develop cracks, low spots, or damaged joints. At first, the issues may seem small, but over time they turn into safety hazards and costly interruptions. In food storage, especially, where compliance with FDA and USDA standards is non-negotiable, those problems can’t be ignored.

That’s why we’re here to share what you need to know about concrete floor repair for food storage warehouses. We’ll explain the common causes of floor damage, the repair solutions available, and why acting early saves you money and stress. Whether you’re running a cold storage facility, a cheese warehouse, or a frozen food distribution center, this guide will help you understand how to keep your concrete floors safe, strong, and ready for the demands of your business.

Why Concrete Floors in Food Warehouses Fail

If you manage a food storage warehouse, you already know the floors go through a lot every single day. Unlike a typical warehouse, cold and refrigerated facilities put unique stress on concrete surfaces. Over time, those stresses lead to problems that you cannot afford to ignore.

One of the biggest issues is temperature fluctuation. Concrete expands and contracts when exposed to cold and then slightly warmer conditions. In freezers, coolers, and loading areas, this constant change eventually creates cracks, surface spalling, and uneven sections of flooring.

Then there’s the impact of heavy equipment traffic. Forklifts, pallet jacks, and other machinery travel across the same pathways all day long. The weight and vibration cause joints to chip away and slab edges to break down. Once that damage starts, it only gets worse with time.

Moisture is another challenge. In cold storage, condensation and frequent washdowns allow water to seep into cracks or weak spots in the floor. This accelerates deterioration, and in freezing conditions, trapped water expands, causing more damage.

And finally, there are hygiene risks. Cracks, potholes, and uneven joints trap dirt, food particles, and bacteria. In a facility that handles cheese, meat, or other food products, this is more than just a cleaning problem. It’s a direct threat to compliance with FDA and USDA requirements.

When you combine all these factors, the result is a warehouse floor that becomes unsafe, inefficient, and costly to maintain. The good news is that with the right repair approach, you can restore your floors, extend their lifespan, and keep your operations running smoothly.

Common Repair Needs in Food Storage Facilities

When it comes to food storage warehouses, the same types of floor problems show up again and again. These issues may start small, but if you don’t repair them quickly, they can lead to compliance violations, safety risks, and higher costs down the line. Here are the most common repair needs we see:

1. Crack Repair

Cracks form from temperature changes, moisture, or heavy loads. Beyond being unsightly, cracks trap dirt and bacteria, which is a serious problem for food safety. We repair and seal cracks to stop further damage and restore a clean, sanitary surface.

2. Joint Repair

Forklifts and pallet jacks put tremendous pressure on slab joints. Over time, this traffic chips away at the concrete edges and creates rough, uneven joints. We rebuild and fill these areas so equipment can move smoothly and safely.

3. Slab Settlement Correction

Uneven slabs are common in cold storage because of soil movement and heavy equipment use. Sunken areas create trip hazards and make cleaning more difficult. We lift and level these slabs to bring the floor back to its original condition.

4. Pothole and Surface Restoration

In high-traffic zones, potholes and worn surfaces are almost unavoidable. They damage equipment wheels, slow down operations, and make sanitation harder. Repairing these spots keeps your facility efficient and safe.

Why Timely Repairs Matter in Cold Food Warehouses

In a food storage warehouse, time is everything. Delaying concrete floor repairs may seem like a way to save money, but the truth is that small cracks and uneven joints never fix themselves. Instead, they grow into bigger issues that cost more to repair and put your operation at risk.

Timely repairs protect your compliance with FDA and USDA standards. A floor that is smooth, level, and easy to sanitize is a must in any facility that stores cheese, meat, or frozen goods. Even a small crack can trap bacteria and raise red flags during inspections.

Repairs done at the right time also improve safety. Uneven slabs and potholes cause forklift accidents, damage equipment, and put your staff at risk of injury. A smooth floor means smoother operations and fewer headaches.

And let’s not forget efficiency. Every hour spent working around damaged flooring is time lost. When your floor is restored quickly and correctly, your team can move faster, your equipment lasts longer, and your warehouse keeps running at full capacity.

Simply put, timely repairs save you money, keep you compliant, and protect your people.

Concrete Floor Repair for Food Storage Warehouses Near Me

If you’ve ever typed “concrete floor repair for food storage warehouses near me” into Google, you’ve probably seen all kinds of options. Some companies suggest tearing out and replacing entire slabs, while others recommend expensive chemical-based fixes. The truth is, most food warehouse operators are looking for something practical, affordable, and long-lasting. That’s where we come in.

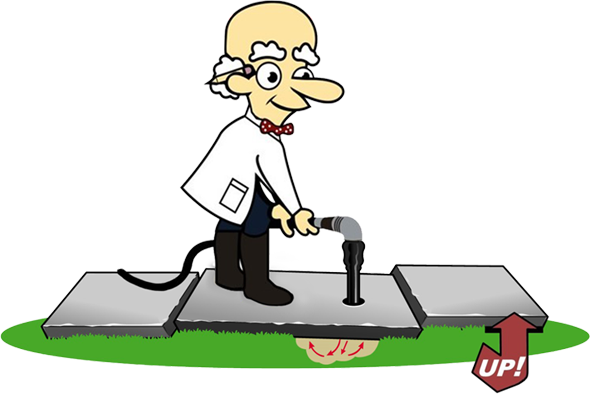

We specialize in repairing warehouse concrete floors using proven techniques that restore strength and stability without unnecessary downtime. One method we often rely on is mudjacking, which lifts and levels sunken slabs by pumping a natural cement-based slurry beneath the surface. This approach saves you money, reduces waste, and provides a reliable fix that can handle the heavy traffic and cold conditions of food storage facilities.

What makes this important for you is the balance between performance and cost. Replacing an entire floor is disruptive and expensive. Quick patch jobs often fail after a few months. But with mudjacking and targeted crack or joint repair, we can give your floor new life and keep it compliant with the strict hygiene standards your industry requires.

If your warehouse floor is uneven, cracked, or damaged by forklifts, now is the time to take action. Small problems only grow bigger when ignored, especially in cold and refrigerated environments.

Concrete Floor Repair in Cold Storage Warehouses in New Jersey

Your concrete floor is the backbone of your food storage warehouse. When it’s in top shape, your operations run smoothly, your staff stays safe, and inspections are easier to pass. But when cracks, settlement, or joint damage appear, they create risks that no facility can ignore.

We understand the unique demands of cold storage warehouses. Floors in these facilities face constant temperature swings, nonstop forklift traffic, and the highest sanitation standards. That’s why we provide repair solutions that are cost-effective, eco-friendly, and built to handle the heavy workload of food storage environments.

If you see uneven slabs, potholes, or cracks forming in your warehouse, don’t wait until they become a bigger problem. Timely repairs save money, prevent compliance issues, and keep your team productive.

We’re proud to be the leading warehouse concrete floor repair company in New Jersey, trusted by cold storage and food warehouse operators throughout the state.

Contact us today to schedule an inspection. Let’s restore your floors and keep your business running strong without unnecessary downtime.

FAQs

How do I know if my food storage warehouse floor needs repair?

If you notice cracks, uneven joints, potholes, or sections of floor that feel sunken, it’s time to consider repairs. In food storage warehouses, even small cracks can trap bacteria and create compliance issues, so it’s best not to wait.

Is mudjacking a good solution for cold storage warehouses?

Yes. Mudjacking uses a cement-based slurry to lift and level concrete slabs, making it cost-effective, eco-friendly, and durable. It works well in cold environments because it stabilizes floors without the need for a full replacement.

How long will repairs take in my warehouse?

Most repairs can be completed within a day, depending on the size of the area and the extent of the damage. The goal is to minimize downtime so your warehouse operations can continue with little to no disruption.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025