IN THIS ARTICLE

Why Floor Thickness Matters in Warehouses

When it comes to warehouses, the concrete floor thickness is more than just a number—it’s a crucial element that determines the longevity and durability of the floor. H2: Why Floor Thickness Matters in Warehouses

When it comes to warehouses, concrete floor thickness is more than just a number—it’s a crucial element that determines the longevity and durability of the floor. Its measurement encapsulates essential warehouse specifications. Warehouse floor slab thickness is particularly critical, as it must be engineered to spread the load evenly.

This aspect of floor slab design is key to ensuring that your warehouse can handle the constant movement of goods, heavy machinery, and traffic without succumbing to cracks, buckling, or deterioration.

Regarding warehouse slabs, adopting the industry-standard thickness of 150 mm to 200 mm is integral to sustaining the heavy loads typical in these environments. The right thickness creates a safer working environment and less maintenance in the long run.

How Thick Should My Warehouse Concrete Floor Be?

Determining the ideal concrete slab thickness for your warehouse floor involves carefully considering several factors, including the load it will bear, the frequency of traffic, and the specifics of warehouse operations.

Generally, following thickness recommendations, a typical floor thickness concrete slab should be at least 6 inches thick to accommodate various weight and traffic conditions.

However, for areas with heavier loads or high-frequency traffic, the right concrete slab thickness may need to be 8 inches or more, ensuring a perfect foundation for your operations.

Consult the ACI 302 Standard chart to identify the precise specifications based on expected wheel loadings, as concrete floors can range anywhere from 5 to 20 inches in thickness for specialized applications.

The Importance of Floor Thickness in Industrial Warehouses

Choosing the right industrial flooring for your warehouse depends on specific needs, such as durability under heavy loads, chemical resistance, or cost-effectiveness. Concrete slab floors, a cornerstone in construction, typically range from 100 mm to over 250 mm in thickness. They cater to intense weight demands and offer high mechanical damage resistance.

Selecting the appropriate concrete slab floor thickness, warehouses benefit from improved sound and vibration absorption, ensuring a quieter and more conducive working environment. They might have a lower installation cost than polymer floors, and proactive maintenance can mitigate repair complexities.

Additionally, reinforcement options such as rebar or wire mesh can be integrated into the floor slab designs to enhance structural integrity, especially in areas where machinery or heavy goods are frequently moved.

Conversely, polymer floors such as epoxy or polyurethane are much thinner, varying from 2 mm for coatings to 9 mm for self-leveling systems. These offer excellent chemical resistance and ease of cleaning, ideal for environments with strict hygiene standards.

They come in various finishes, including colors and safety markings, although they can be more susceptible to mechanical damage due to their reduced thickness and lack of reinforcement options.

Concrete is often the best choice for warehouses due to its unmatched load-bearing capacity and minimal maintenance over time. Its robust nature ensures it remains a cost-effective, long-term flooring solution for most industrial uses.

Why choose us for your warehouse concrete floor repair needs

You have several warehouse concrete floor repair options, but why settle for the average when you can have the best? Our team excels in converting your flooring challenges into robust, efficient solutions. When you choose us, you’re banking on:

- Expertise: We bring years of industry-specific knowledge, ensuring that your floor meets the highest standards.

- Quality Materials: We use superior-grade concrete and repair materials that ensure the endurance of your floors.

- Customized Solutions: Our approach is tailored to your unique operational needs, offering the best outcome for your floor’s thickness, tolerance, and finish.

- Durability Guarantee: With our precise repair techniques, we promise extended durability, reducing the likelihood of recurring issues.

- Customer Support: From consultation to post-repair service, our customer support is with you every step of the way.

Please don’t leave your warehouse floor to chance; by choosing us for your warehouse floor repair, you are investing in the future of your business’s operational efficiency.

FAQs on Warehouse Concrete Floor Thickness

How Does Soil Subgrade Affect Decisions on Slab Thickness?

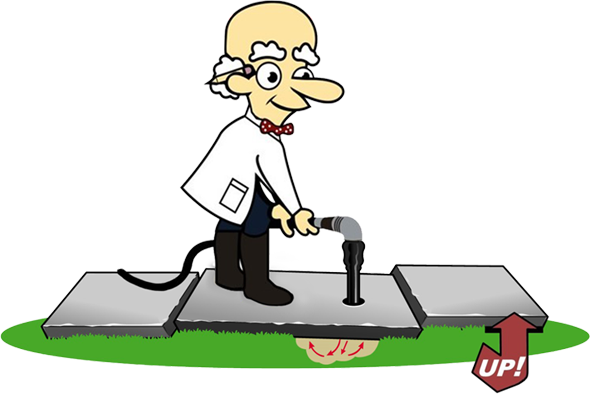

The soil subgrade is pivotal in determining the optimal slab thickness for your warehouse. Different soil types have varying load-bearing capacities that directly impact the concrete floor’s stability and integrity.

Proper subgrade preparation, including ensuring a clean, textured base slab surface, is crucial for the ensuing steps. A thinner slab might suffice if the subgrade comprises firm, compacted soil.

However, weak or poorly compacted soils would require a thicker slab to ensure adequate support and minimize the risk of cracking or settling, especially in areas with a high clay content.

It’s essential to have a geotechnical evaluation to assess the soil’s properties, enabling you to make an informed decision on slab thickness and whether additional measures, such as an aggregate base layer, are necessary for drainage and support.

How thick should a concrete slab be for heavy trucks?

The concrete slab needs to be significantly robust for heavy trucks to withstand the pressure and prevent cracking. As a rule of thumb, slabs intended for heavy trucks should be 150 mm to 200 mm (6 to 8 inches) thick.

This additional thickness provides the necessary support to endure the repeated stress from heavy vehicles and extends the lifespan of the pavement by reducing maintenance issues later on. Consider reinforced concrete options or post-tension slabs for even better performance in high-traffic areas.

Reinforcing with rebar can be a strategic way to augment the thickness of the concrete slab and its ability to support heavy truck loads.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025