IN THIS ARTICLE

Discover how a Timely Industrial Concrete Floor Repair Can help improve the safety Standards of your warehouse

In every warehouse, cold storage facility, or industrial plant, the floor plays a bigger role than most people realize. Your concrete floor isn’t just something you drive forklifts across or store pallets on. It’s the foundation of daily operations, and when it starts to fail, safety standards can take a serious hit.

Cracks, uneven slabs, and worn-out joints might look like minor issues at first. But over time, they can create trip hazards, damage equipment, slow down workflow, and even put your facility out of compliance with OSHA or food safety standards. For industries that handle cold storage or food products, the stakes are even higher because damaged floors can trap moisture and bacteria, creating hygiene risks.

The truth is, waiting too long to repair a concrete floor only makes problems worse. Small cracks spread, potholes deepen, and before you know it, your team is dealing with accidents, costly downtime, or failed inspections.

That’s why timely industrial concrete floor repair isn’t just about fixing concrete. It’s about protecting people, keeping operations smooth, and giving your business the confidence that safety standards are being met. In this article, we’ll show you exactly why acting fast matters and how the right repair solutions can make your warehouse floor safer and stronger.

Common Safety Risks from Damaged Industrial Concrete Floors

When concrete floors in industrial and cold storage facilities start breaking down, safety becomes one of the first things at risk. Here are the most common issues we see:

Trip and Fall Hazards

Cracks, holes, and uneven slabs may not seem like a big deal, but they create hidden dangers for workers on foot. Even a small trip can lead to serious injury, lost workdays, and workers’ compensation claims.

Equipment Damage

Forklifts and pallet jacks constantly roll over your floors. When they hit broken joints or uneven sections, the equipment takes the impact. This leads to costly repairs, shortened lifespan of machines, and unexpected downtime.

Load Instability

Damaged floors can’t always support heavy loads properly. Pallets may tilt or shift, increasing the risk of dropped goods, damaged products, and worker injury—especially in cold storage warehouses where food safety is critical.

Hygiene and Compliance Issues

Cracks and potholes collect water, dirt, and bacteria. In food storage warehouses, this creates a serious compliance problem. Not only can it threaten product integrity, but it can also draw attention from safety inspectors.

Slowed Productivity

Workers move more slowly and more cautiously in damaged areas. Add in equipment malfunctions and delays, and suddenly your warehouse isn’t running as efficiently as it should.

Addressing these risks quickly doesn’t just protect your team. It keeps your facility compliant, efficient, and ready for smooth operations.

The Role of Timely Floor Repair in Meeting Safety Standards

When it comes to industrial and food storage facilities, safety isn’t optional—it’s a requirement. OSHA regulations, food safety standards, and internal company policies all demand that your warehouse floor remain safe for both workers and stored products. That’s where timely concrete floor repair comes in.

Prevents Accidents Before They Happen

By addressing cracks, uneven slabs, or failing joints early, you stop hazards from turning into injuries. A level, well-maintained floor reduces slips, trips, and falls, keeping your team safe and productive.

Keeps You in Compliance

Cold storage and food warehouses are heavily regulated. Flooring issues that collect bacteria or allow water pooling can lead to compliance violations. Fixing problems quickly shows inspectors—and your clients—that safety and hygiene are priorities.

Protects Equipment and Inventory

Forklifts, pallet jacks, and heavy loads rely on stable ground. Timely repairs prevent damage to machinery, reduce downtime, and keep products secure. That’s especially critical when dealing with temperature-sensitive goods like dairy or frozen foods.

Saves Money in the Long Run

A small crack is cheaper to fix today than a full slab replacement tomorrow. Timely repairs extend the life of your floor and lower overall maintenance costs while keeping operations running smoothly.

In short, fixing warehouse floors on time isn’t just a maintenance task—it’s a direct investment in safety, compliance, and long-term efficiency.

Benefits of Professional Industrial Concrete Floor Repair

While small cracks or chips may seem manageable, industrial concrete floor repair is not something to leave to quick fixes or temporary patching. Bringing in a professional repair team offers long-lasting results that go beyond what DIY or short-term solutions can achieve.

Expertise and Precision

Professionals know how to identify not just the visible damage, but also the root causes—such as settlement, moisture intrusion, or traffic-related stress. This ensures the repair addresses the real problem and not just the surface.

Long-Lasting Repairs

Instead of patch jobs that fail within months, professional repair methods restore the floor’s strength and durability. Done right, your concrete floor can handle heavy forklift traffic and cold storage conditions for years without repeated fixes.

Compliance and Safety Assurance

A certified repair team understands OSHA requirements and food warehouse standards. That means the repairs are done with hygiene and safety in mind, keeping you compliant during inspections.

Minimal Downtime

Professionals work efficiently and use the right materials for the job, so your operations are interrupted as little as possible. For busy warehouses, this saves both time and money.

Cost-Effective Investment

By fixing floors correctly the first time, you avoid recurring expenses, equipment damage, and lost productivity. A proper repair saves money in the long run.

At the end of the day, professional floor repair isn’t just about concrete—it’s about protecting your people, your equipment, and your reputation.

Industrial Concrete Floor Repair Services Near You in New Jersey, USA.

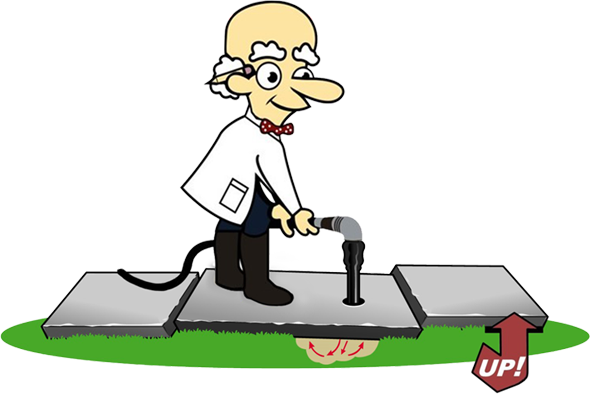

When you search for industrial concrete floor repair near me, what you really need is a trusted partner who understands the unique challenges of warehouse and cold storage environments. That’s where we come in.

As the leading provider of warehouse floor repair services in New Jersey, we combine affordability, reliability, and eco-friendly repair methods to deliver results that last. Whether your floor is showing cracks, uneven slabs, or heavy wear from forklift traffic, we know how to restore it quickly and effectively.

Our approach isn’t just about fixing concrete—it’s about protecting your workers, equipment, and products while keeping your facility inspection-ready. By acting now instead of waiting, you’ll save money, reduce downtime, and avoid safety risks that could disrupt operations.

Timely repairs make all the difference. From preventing accidents to staying compliant with safety and hygiene standards, keeping your concrete floors in top shape ensures smoother operations and peace of mind.

If your warehouse or cold storage facility needs reliable floor restoration, we’re here to help. Contact us today for your warehouse concrete floor repair in New Jersey. Let’s keep your floors safe, strong, and inspection-ready.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025