IN THIS ARTICLE

Learn How to Select the Correct Industrial Floor Sweeper for Your Warehouse Concrete Floor

If you run a warehouse, you know how important it is to keep your floors clean. A dirty floor is not just ugly. It can be dangerous. Dust, dirt, and debris can cause slips, damage equipment, and even hurt your staff.

We repair warehouse concrete floors here in New Jersey, and we’ve seen how much damage bad cleaning habits can do. This blog post is not a sales pitch. We don’t sell sweepers, and we don’t offer floor cleaning services. But we do repair concrete floors, and that gives us a front-row seat to what works and what doesn’t.

So, if you’re thinking about buying an industrial sweeper for your warehouse, we want to help you choose the right one.

You may not think a sweeper has much to do with floor damage, but it actually does. The wrong machine can wear out your concrete, crack it, or make small problems worse.

Picking the right sweeper is part of good warehouse maintenance, and it could save you from expensive repairs down the road.

Let’s get into it.

Why Choosing the Right Sweeper Matters

Concrete warehouse floors take a lot of beating. Forklifts roll over them. Pallets get dragged across them. And when dirt builds up, it acts like sandpaper, grinding away the top layer of your floor. I’ve repaired floors where the damage started because no one cleaned properly. Or they used the wrong equipment.

A good industrial sweeper helps you avoid that. But a bad one can scratch your surface, push debris into cracks, and make small issues worse. So, when choosing a sweeper, you’re not just thinking about cleaning. You’re thinking about protecting your floor.

Think About the Debris

Start by asking yourself: What kind of debris do I have?

Are you dealing with fine dust? Or do you see wood chips, metal shavings, or packing material on the floor?

Fine dust needs a sweeper with a strong vacuum and a good filter. Metal or wood bits need strong brushes and more power. If your warehouse handles a mix, you’ll want a machine that can handle both heavy debris and fine dust. Choosing the wrong type of sweeper here can lead to poor cleaning and even damage to the brushes or the floor.

How Big is Your Warehouse?

The size of your floor makes a big difference. If you have a small warehouse with narrow aisles, a walk-behind sweeper might be enough. They’re easy to move around, and they’re cheaper.

But if your space is large or open, a ride-on sweeper will save you time. They cover more ground faster. You don’t want your staff spending all day cleaning when a ride-on machine can do it in an hour. That said, they’re also more expensive and take up more storage space.

Indoor or Outdoor Use?

Some sweepers are made for both inside and outside. Others are not. Make sure you know the difference. If you try to use an outdoor sweeper indoors, you could end up with more dust in the air. That’s bad for both your staff and your equipment.

Your concrete warehouse floor is indoors. So, pick a sweeper that is designed for indoor use. If your building also has loading docks or outdoor storage, then you might want a model that can handle both. Just be sure it has proper filters and won’t kick up dust inside.

Check the Condition of Your Floor

This part is close to our hearts. We fix floors, so we need to say this clearly: Clean floors won’t last if the floor is already damaged.

Sweepers work best on smooth, even concrete. If your floor has cracks, holes, or uneven joints, a sweeper could make it worse. We’ve seen machines get stuck in cracks, or have their brushes torn up by broken surfaces.

If your floor has damage, fix it before you start sweeping regularly. You don’t want to spend thousands on a new machine, only to find it doesn’t work right because the floor isn’t ready for it.

Dust Control is a Big Deal

Some warehouses have to follow strict rules about air quality. If that’s you, don’t ignore this part. Pick a sweeper that comes with a good filter system, like a HEPA filter.

These filters trap tiny dust particles so they don’t get into the air. That keeps your workers safe and your building cleaner. Even if you’re not under a regulation, it’s still a good idea. Breathing in dust every day isn’t good for anyone.

How is the Sweeper Powered?

Sweepers come in different power types. Some plug into the wall. Some run on batteries. Others use propane or gas.

- Battery-powered sweepers are quiet and don’t make fumes. They’re great for indoor use.

- Electric corded models work well if your space is small and you don’t mind dragging a cord.

- Propane or gas-powered sweepers are better for large, open, or outdoor spaces.

Think about your needs. If you run 2 or 3 shifts, you might need a battery-powered unit with a backup battery. If you only clean once a day, something simpler could work.

Don’t Forget Maintenance

All machines need care. Industrial sweepers are no different. Brushes wear out. Filters need changing. Motors need checks.

Pick a model that’s easy to service. Ask the seller how often it needs maintenance. Some machines are built to last and need little care. Others might give you problems if you don’t stay on top of them.

A poorly maintained sweeper can drag parts across the floor, leave streaks, or even damage the surface. That’s when we get called to do repairs. And trust us, it’s cheaper to prevent than to fix.

Common Mistakes You Should Avoid

Let’s quickly share some mistakes we see all the time:

- Using the wrong sweeper indoors. Some businesses try to save money by using outdoor machines inside. It doesn’t work.

- Cleaning a broken floor. Don’t sweep over cracks or holes. Fix them first.

- Not reading the manual. Every machine has its own instructions. Read them.

- Skipping daily checks. A 2-minute check can stop a big repair later.

- Ignoring the brush type. Use the right brushes for your floor and debris type. Too hard, and they can scratch. Too soft, and they leave debris behind.

Fix First, Then Sweep

Here’s a bit of advice most cleaning machine sellers won’t give you: if your floor is in bad shape, don’t buy a sweeper yet.

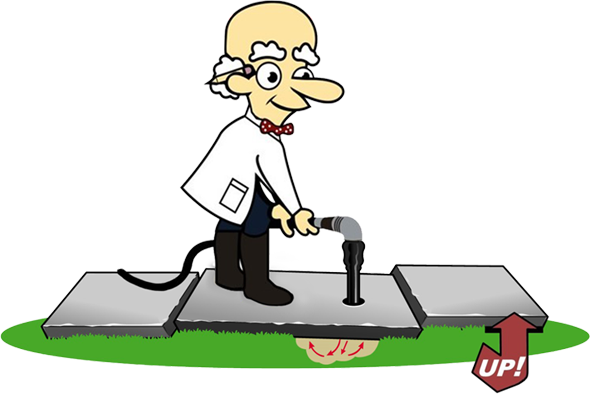

Broken concrete can ruin a new machine. It can also stop the sweeper from doing its job. Loose dust and debris get pushed into cracks. Over time, that wears the cracks down more and makes them wider.

If you notice any of the following:

- Uneven floor spots

- Cracked joints

- Chips near loading docks

- Areas that hold water

Call a repair expert. If you’re in New Jersey, that’s where we come in. Warehouse Concrete Floor repair will take a look and help you fix those areas before you drop thousands on a new sweeper.

You Don’t Need the Most Expensive Sweeper

Many people think the best solution is the most expensive machine. That’s not always true. W’ve seen warehouses buy high-end ride-on sweepers when all they really needed was a basic walk-behind.

Start with your needs. Think about the debris, your floor condition, the size of your space, and how often you’ll be cleaning. The best sweeper is the one that matches your warehouse, not the one with the biggest price tag.

Final Thoughts

Choosing the right sweeper is about more than just cleaning. It’s about protecting your investment—your floor.

We’ve seen warehouses with new sweepers and cracked floors. We’ve also seen places with old sweepers and perfect floors.

The difference?

Knowing what your floor needs and acting on it.

If you’re in New Jersey and your warehouse floor is cracked, chipped, or worn down, don’t wait. Let us help you repair it before you invest in a cleaning routine. A good floor and a good sweeper go hand in hand.

Need advice or a free floor checkup? We are just a call away.

Stay safe, and sweep smart.

FAQs

Can sweeping a damaged warehouse floor make it worse?

Yes, sweeping a damaged concrete floor can make things worse. Sweepers can drag debris into cracks, wear out broken edges, or get stuck in uneven surfaces. Always repair cracks or chips first to avoid bigger problems later.

How often should I inspect my warehouse floor before using a sweeper?

It’s best to inspect your concrete floor weekly and especially before running a sweeper. Look for cracks, uneven areas, and surface damage. Regular checks help you spot issues early and prevent both sweeper damage and costly floor repairs.

Do industrial sweepers damage concrete floors?

Not if you choose the right one and use it properly. Sweepers with the wrong brush type or poor maintenance can scratch or wear out the surface. Always match the machine to your floor type and make sure the concrete is in good condition before sweeping.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025