IN THIS ARTICLE

Cold storage facilities are some of the toughest environments for concrete floors. The temperature changes, heavy forklift activity, constant movement of goods, and the ever-present moisture all work together to stress the slab.

If you manage a warehouse in New Jersey or Eastern Pennsylvania, you already know that even a small floor issue can slow down your workflow. A simple crack can grow, a joint that starts to chip can turn into a trip hazard, and uneven areas can shake your forklift operators and damage products on pallets.

The truth is that concrete floors in cold storage buildings do not behave like floors in regular warehouses. They experience unique conditions that make them more likely to crack, settle, or develop surface defects.

Once the cold air meets moisture inside the slab, things can get worse quickly. This is why staying ahead of repairs is important. If you understand the cause, you can prevent recurring problems and save money on long-term maintenance.

In this article, we walk you through what causes concrete issues in cold storage environments, the right way to diagnose the problem, and the practical solutions you can use to fix or prevent further damage.

We will also talk about uneven floors, mudjacking, and why some repair materials, especially polyurethane injections, may not be the best choice for cold storage floors.

Our goal is straightforward: to provide you with a guide that helps you make informed decisions for your warehouse, ensuring your operations run smoothly and safely. And if you ever need help, we have been supporting warehouse owners with lasting concrete solutions for the last 25 years.

Why Concrete Floors Fail in Cold Storage Environments

Thermal Cycling and Temperature Differential

Concrete reacts to temperature changes, and cold storage facilities put this reaction to the test every day. When temperatures inside a freezer or cooler drop, the concrete contracts.

When areas next to the cold room are warmer, the slab expands. With this constant movement happening day after day, the floor begins to experience stress. Cracks are usually the first visible sign. They might start thin, but over time they widen or travel across large areas of the slab.

Moisture, Vapor Drive, and Frost Heave

Moisture is another major cause of floor issues. Most cold storage floors sit above insulation and a vapor barrier. When the vapor barrier is damaged or was never installed correctly during construction, moisture from the ground can rise into the concrete.

As soon as this moisture reaches colder zones, it freezes. Frozen moisture expands. That expansion creates pressure inside the slab, which can cause pop outs, spalling, or hollow sounding sections. In more serious cases, frost heave lifts the floor and leads to uneven surfaces that are unsafe for forklifts.

Mechanical Wear: Forklifts, Pallets, and Dock Activity

Mechanical stress also plays a big role. Forklifts in cold storage operate for long hours. They make sharp turns, carry heavy loads, and move at quick speeds. Over time, these movements wear down joints, surface paste, and expose aggregate.

Areas near racking lines or loading docks are especially vulnerable. When joints begin to break apart, they create bumps that transfer impact directly to equipment wheels. The more the slab vibrates, the faster the damage spreads.

Cleaning practices can add another layer of stress. Regular washdowns, especially with hot water, hit the cold slab and create thermal shock. The surface responds by expanding and contracting quickly, which weakens the top layer and may lead to surface delamination.

Cold storage floors fail because they are put under constant, unusual pressure. Understanding these causes helps you apply the right repair method and prevent recurring issues.

How to Diagnose the Problem: Quick Checks and Tests

Visual Signs

Start with a visual inspection. Walk through the warehouse and look for cracks, chipped edges, exposed aggregate, discoloration, or hollow-sounding spots. Pay close attention to joints, loading dock areas, and the paths your forklifts follow the most. Wide cracks or cracks along a straight line may indicate movement below the slab. Surface flaking or peeling often points to delamination caused by moisture or thermal shock.

Flatness and Levelness

Cold storage operations depend on smooth floors, especially if you use high reach equipment. Uneven floors can cause load shifts, unstable pallet movement, and reduce forklift efficiency. A straightedge, laser level, or formal FF FL test can determine how much the floor has moved. If an area is sunken or raised by more than a few millimeters, it should be flagged for repair.

Moisture Testing and Infrared Scans

Moisture testing is one of the most important steps. Many floor failures are linked to moisture trapped under the slab. Surface moisture meters help, but deeper readings through drilled holes or core samples give better results. Infrared scans can detect cold or warm pockets that suggest moisture movement under the slab.

Hollow Sounds

Tap questionable areas with a hammer or metal tool. A hollow sound usually means the surface layer has separated from the concrete below. This can happen because of moisture, improper construction, or repeated freeze-thaw cycles.

Building History and Past Repairs

Check the building’s history. Have freezer temperatures changed recently? Was there a plumbing or drainage issue? Were cuts made to the slab in the past? Understanding the history helps pinpoint the cause.

A thorough diagnosis sets the stage for a lasting repair. Without it, repairs often fail shortly after completion.

Repair and Prevention Solutions for Uneven Warehouse Floors

Minor Surface Repairs

When unevenness comes from small surface damage, grinding and patching are often enough. Diamond grinding removes high spots, evens out minor differences, and creates a smooth, durable surface for forklifts. For cracks or chipped joints, repairing with cement-based materials restores the integrity of the floor.

Mudjacking for Settled Floors

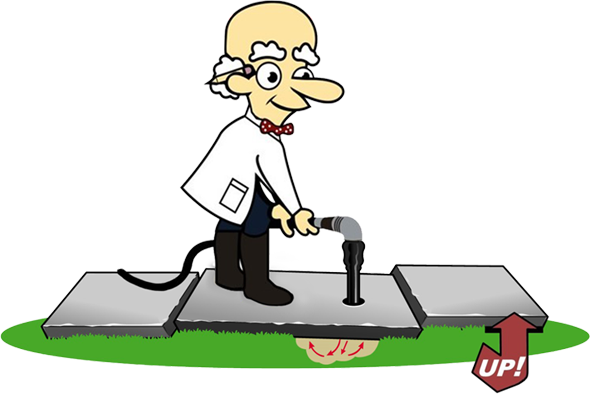

Mudjacking is one of the most reliable methods for raising settled concrete. A cement-based slurry is pumped under the slab, filling voids and lifting the concrete to its proper level. This provides stable support and prevents further settling.

In cold storage, mudjacking works consistently because it does not expand unpredictably like polyurethane injections. Polyurethane expansion in cold temperatures can cause additional cracking or uneven lifting, which is why we do not use or encourage it for freezers and cooler floors.

Joint Repairs

Damaged joints need attention. Clean the edges, remove loose material, and fill the joint with a cement-based repair compound. Well-maintained joints reduce stress on forklift wheels and prevent new cracks from forming.

Addressing Moisture Issues

When uneven floors are caused by moisture, you may need to fix drainage problems or inspect the vapor barrier and insulation below the slab. Sometimes a localized repair is enough, but in cases of severe frost heave, a more thorough approach is required.

Preventive Measures

Preventive steps include regular inspections, moisture checks, and early repairs. Proper wheel selection for forklifts, good housekeeping practices, and consistent maintenance help the floor last longer. Fixing minor problems early avoids major downtime later.

Preventive Measures and Best Practices for Cold Storage Warehouses

Proper Slab Design: Insulation and Vapor Barriers

A well-designed slab is key to long-lasting performance. A correctly installed vapor barrier stops ground moisture from reaching the concrete. Insulation reduces frost penetration, which prevents frost heave. Older warehouses may require upgrades during major repairs.

Door and Threshold Considerations

Cold storage floors are most vulnerable near doors. Warm, moist air entering cold rooms creates condensation and frost near thresholds. Heated thresholds and air curtains can reduce moisture accumulation and protect the concrete.

Joint Maintenance

Regular joint maintenance is critical. Forklifts strike joints constantly, and damaged joints accelerate cracking. Keeping joints filled and edges protected keeps slabs stable and prevents long-term damage.

Surface Treatments

Epoxy coatings can improve surface durability if the slab is dry, clean, and stable. Moisture testing and surface preparation are essential. Applying coatings over damp concrete will lead to failure.

Cleaning Practices

Steady cleaning temperatures are important. Avoid thermal shocks like hot water on cold slabs. Automated cleaning systems should match warehouse temperature conditions.

Employee Training

Train your team to spot early signs of damage. Hairline cracks today may become forklift hazards in a few months. Quick reporting allows repairs before issues grow.

When to Call a Professional

Red Flags

Structural cracks, persistent moisture, recurring settlement, and widespread spalling indicate the need for a professional inspection. These issues often go beyond the capability of in-house maintenance.

Professional Inspections

A consultation from a structural engineer may be needed to conduct moisture tests, core samples, hammer sounding, and flatness checks. Cold storage floors often hide problems beneath the surface, making thorough testing essential.

Choosing the Right Contractor

Ask about experience with cold storage environments. Floors in freezers require knowledge of thermal behavior, insulation, vapor barriers, and stress from forklift traffic. A clear repair plan, timeline, and explanation of materials should be provided. Ask for references from similar projects to ensure reliability.

Long-Term Solutions

Professional repairs correct the root cause, not just the symptoms. Acting early reduces downtime, keeps floors safe, and ensures smooth warehouse operations.

For over 25 years, we have been helping warehouse owners across New Jersey and Eastern Pennsylvania solve concrete problems in cold storage environments.

We offer lasting, practical warehouse floor repair solutions that keep your operations safe and efficient. If your warehouse floor is showing cracks, unevenness, or settlement, contact us for a professional inspection and a repair plan you can trust.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025