IN THIS ARTICLE

Discover How Uneven Warehouse Floors Can Cause Forklift Failures in the Warehouse

If you run a warehouse in New Jersey or Eastern Pennsylvania, you already know how busy things can get. Forklifts are always moving, staff are meeting deadlines, and products need to flow smoothly across the floor.

With all that pressure, the condition of your concrete floor is easy to overlook. Most owners only pay attention when cracks spread, joints begin to chip, or forklifts start making unusual noises in certain spots. By that time, the uneven surface may already be affecting productivity, safety, and even the lifespan of your equipment.

Uneven floors are more common than they appear. Concrete may look strong, but it reacts to soil movement, moisture, temperature changes, and years of heavy traffic. When a slab settles or dips, forklifts end up driving over small height differences every day.

Those little bumps create stress on machines that were designed for smooth surfaces. Over time, tires wear faster, masts shift slightly, and operators feel the strain in their handling.

We have spent years helping warehouse owners fix these issues. A small, uneven spot can turn into a costly problem if ignored, but the right repairs restore stability and make daily operations safer.

In this article, we break down why warehouse floors become uneven, the forklift problems they cause, the safety risks involved, and how you can stay ahead of the damage. Understanding the root of the problem helps you protect your equipment, your workers, and your bottom line.

Why Warehouse Floors Become Uneven

Warehouse floors do not become uneven overnight. It usually happens slowly, over years of use and environmental changes. Concrete is strong, but its strength does not prevent it from reacting to stress. If something below or around the slab shifts, the concrete will eventually reflect that movement.

Most warehouse owners only notice the result, not the cause. Understanding the underlying reasons helps you decide the best way to address the problem and prevents you from repeating the same cycle later.

Heavy Load Cycles and Repeated Traffic

Forklifts carry thousands of pounds back and forth, often following the same paths every day. When you combine the weight of the load with the dynamic movement of the forklift, it creates a cycle of pressure on the slab. Over time, the concrete begins to develop hairline cracks, especially around joints.

Once these cracks form, the edges of the slab lose some of their support. Each time a forklift wheel hits that weakened spot, the pressure pushes the slab down slightly. The movement is small, but as it repeats daily, the slab settles unevenly.

This is one of the most common issues we see in older warehouses or facilities with constant heavy operations like distribution centers or cold storage buildings. When the floor starts to dip in these high-traffic paths, forklifts respond by vibrating more, bouncing over low spots, and putting extra stress on their components.

Poor Subgrade or Soil Settlement

The soil under a warehouse floor matters more than many people realize. If the ground was not properly compacted before the concrete was poured, it may begin to settle years later. Sometimes the soil itself is too soft or too loose.

Other times, water moves through the soil and washes out fine particles, creating empty pockets. When this happens, the concrete above begins to sink in certain areas. You may notice small dips, uneven joints, or cracks forming near walls or heavy equipment zones.

Because the soil movement is hidden, the problem continues until the floor visibly shows distress. By the time most owners see gaps or feel uneven vibration when forklifts pass, the slab has already lost proper support. At that point, simple patching will not solve the real issue because the soil beneath is still unstable.

Moisture Intrusion and Freeze-Thaw Cycles

Moisture is another major contributor to uneven floors. It can come from groundwater, poor drainage, plumbing leaks, or seasonal humidity. Concrete absorbs moisture, and when temperatures drop, that moisture expands. The freeze thaw cycle weakens the slab. Repeated cycles lead to cracking, surface spalling, and corner breaks around joints.

In areas like New Jersey and Eastern PA, freeze-thaw cycles are common. Every winter, concrete expands and contracts.

Over many years, this movement has created enough stress to distort parts of the slab. Forklifts passing over these weakened points push them down even more, increasing the unevenness and making the problem more noticeable.

Aging Concrete and Joint Deterioration

Even the best concrete does not last forever. As it ages, it begins to weaken, especially at the joints. Joint deterioration is a major cause of uneven floors.

Once the joint filler wears out or the edges start to chip, forklifts ride over raw concrete edges. Each pass breaks the joint down a little more. Without support, the slab corners begin to sink, creating a step-down effect that grows deeper over time.

Aging floors are very common in older warehouses, manufacturing plants, and commercial buildings that were built 20 to 40 years ago. Many of these floors were not designed for the weight of modern forklift equipment, which means they begin to fail earlier than expected.

Common Forklift Problems Caused by Uneven Floors

Uneven floors not only affect the building. They directly impact how your forklifts behave. Even small dips or bumps on the warehouse floor can create large mechanical challenges for equipment that relies on stability to operate safely. We have seen forklifts damaged in completely avoidable ways simply because the floor beneath them was not level.

Wheel and Tire Damage

Forklift tires are designed for smooth surfaces. When the floor has dips, raised joints, or cracks, the tires face continuous impact. This increases wear and can cause flat spots on cushion tires or chunking on pneumatic tires.

Once the tire is damaged, the forklift loses stability. Operators may feel a vibration or wobble when driving. Damaged tires also reduce traction, making load handling less predictable.

If tires constantly wear out earlier than expected, the floor is usually part of the problem. Replacing tires repeatedly becomes expensive, especially across a large fleet.

Mast Misalignment and Lifting Instability

Forklifts rely on a straight and balanced mast to lift heavy loads safely. When a forklift drives over uneven surfaces, the mast experiences sudden jolts.

Over time, these impacts cause misalignment. Once the mast shifts slightly out of line, loads may tilt, shake, or wobble during lifting.

Operators often notice the issue when they try to stack pallets and the forks do not slide smoothly into the rack. Misalignment also increases the risk of dropped loads, which can damage products and lead to serious safety incidents.

Increased Wear on Bearings and Suspension

The constant vibration caused by uneven floors places stress on bearings, bushings, and the forklift suspension. These components are not meant to absorb continuous shock. When the impact repeats daily, the parts begin to loosen or fail earlier than expected. Repairs can be expensive, and the downtime affects productivity.

In many warehouses where we perform concrete repairs, owners often tell us they used to assume the forklifts were poor quality or were being handled improperly. Once the floor is fixed, the sudden drop in maintenance costs proves the real cause was the uneven slab.

Hydraulic Leaks Triggered by Excessive Vibration

Hydraulic systems are sensitive to vibration. When forklifts bounce over low spots or raised joints, the vibration travels through the entire frame, putting pressure on hoses and seals. Over time, the seals weaken and begin to leak. Hydraulic leaks are dangerous because they reduce lifting power and increase the risk of accidents.

Leaks also cause downtime and require immediate repair. When several forklifts in the same warehouse develop hydraulic issues around the same time, it is often a sign that the floor needs attention.

Slower Travel Speeds and Downtime

Operators naturally slow down when they feel unstable. Uneven floors force them to adjust their speed to avoid damaging the forklift or the load. This reduces overall productivity. If multiple sections of the warehouse floor have become uneven, the accumulated time loss adds up.

We have seen warehouses lose hours each week because forklifts cannot maintain normal speeds. Once the floor is repaired and leveled, operators move confidently again and the workflow returns to normal.

Safety Risks for Workers and Warehouse Operations

When people think of safety in a warehouse, they often think about PPE, training, and proper equipment use. While all those are important, the condition of the floor is just as critical. An uneven floor does more than affect machines. It creates risks for everyone who enters the building.

Load Tipping and Product Loss

Uneven floors increase the chance of load tipping. When a forklift hits a dip or raised joint, the sudden shift can cause the load to tilt or fall. Even a small tilt can be enough to destabilize a tall stack of boxes or a heavy pallet. Tipped loads damage products, create cleanup headaches, and can put workers in danger.

Many warehouses deal with frequent product loss without realizing the floor is part of the problem. Smooth floors reduce sudden jarring, which keeps loads stable during transport and stacking.

Operator Fatigue and Handling Errors

Forklift operators feel every bump and vibration through the seat and steering column. Over an eight or ten hour shift, this takes a physical toll. The constant shaking leads to fatigue, which increases the chance of mistakes. When workers are tired, their reaction time slows, and their ability to handle loads safely decreases.

An uneven floor also makes steering more difficult. Operators struggle to keep the forklift steady, especially when turning or lifting. This extra effort increases stress and reduces job satisfaction.

Higher Risk of Workplace Accidents and OSHA Violations

Accidents involving forklifts are common nationwide, and uneven floors are a contributing factor. A sudden jolt from hitting a low spot or raised edge can cause an operator to lose control. If the forklift swerves, tips, or drops a load, someone can get seriously hurt.

Uneven surfaces can also be considered a workplace hazard under OSHA guidelines, especially if they contribute to accidents. If an incident occurs and investigators find the floor was not maintained properly, it becomes a legal and compliance issue for the warehouse owner.

Smooth and level floors reduce these risks significantly. When the floor is even, forklifts operate in a predictable way. Workers handle loads with confidence, and the number of safety incidents drops.

How to Identify Floor Issues Before They Cause Forklift Failure

Catching warehouse floor problems early can save you money, reduce downtime, and prevent more serious issues. The challenge is that many early warning signs are subtle. They start small, and because warehouse floors are large, it is easy to overlook them. The key is knowing what to look for and paying attention to small changes.

Signs Your Warehouse Floor Is Sinking or Settling

Some of the most common indicators include small dips that become noticeable when a forklift passes over them. Operators might report feeling a bump or vibration in the same spot every day. Another sign is cracking that widens over time. If cracks begin to collect dust or debris, it usually means the slab is slowly moving apart.

You may also notice areas where water pools after cleaning or rainwater leaks. Pooling water is a strong sign that the concrete is no longer level. If the slab is sinking, the water naturally flows to the lowest point.

When Joint Separation Becomes a Structural Hazard

Joint deterioration is often ignored until it becomes a tripping hazard or a forklift hits it hard enough to damage a tire. If you see chipped edges, wide gaps, or joint filler that has worn away, the slab is beginning to lose support. The longer the joint stays open, the faster the surrounding concrete breaks down.

Forklifts hitting these joints repeatedly increase the separation. If the joint starts to look uneven or if the slab on one side sits lower than the other, the condition needs immediate attention.

Using Precision Floor Leveling Scans and Straightedge Testing

For warehouses with heavy operations, getting a professional inspection can help identify problems you may not see. Straightedge testing reveals dips that are not visible. Advanced floor scans identify height variations across large areas. These tools help you determine whether your floor is within acceptable flatness standards for forklift use.

We often use these techniques before planning any repair. It gives us a full picture of what is happening beneath the surface and helps us create a long-lasting solution.

Repair and Prevention Solutions for Uneven Warehouse Floors

Fixing uneven warehouse floors is not just about smoothing the surface. The real goal is restoring proper support under the slab so the problem does not return. Over the years, we have helped warehouse owners, facility managers, and distribution centers in New Jersey and Eastern PA solve their concrete issues with lasting solutions based on the real cause of the problem.

Concrete Slab Lifting and Leveling With Mudjacking

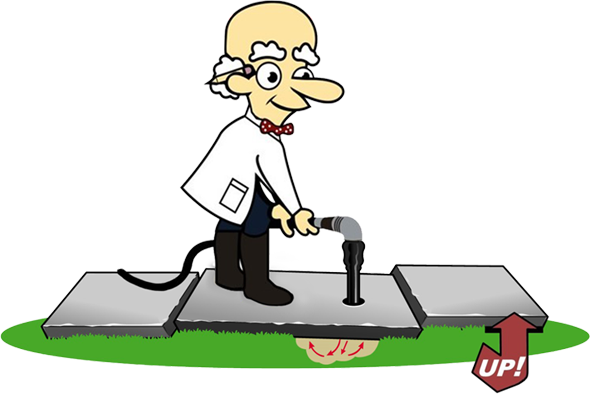

We use mudjacking because it is reliable, cost-effective, and proven. Mudjacking involves pumping a thick mixture of soil, sand, and cement underneath the slab. This fills empty voids, stabilizes weak areas, and lifts the concrete back to level. It restores proper support, which is the most important step when dealing with sinking or settling floors.

We do not use or encourage polyurethane foam lifting. Foam may seem modern, but it can trap moisture, it is toxic, flammable, and sometimes expands unpredictably. Mudjacking is more natural, environmentally safe, and works better for large warehouse slabs that demand long-term stability.

Once the slab is lifted and supported, forklifts operate smoothly again. The vibration decreases, and many maintenance issues disappear almost immediately.

Joint and Crack Repair to Stop Further Deterioration

Repairing joints and cracks is just as important as leveling the slab. After lifting, we seal the joints to protect the edges from damage. Proper joint repair reduces the impact forklift tires experience when crossing those lines every day.

Cracks also need to be filled, not just patched. We make sure the cracks do not grow or allow water to seep in and weaken the soil below. This step prevents future settlement and keeps your warehouse floor functioning correctly.

Surface Grinding and Smoothing for High Traffic Areas

Some warehouse floors have raised spots or uneven transitions that cannot be lifted. In those cases, surface grinding is the right solution. Grinding smooths high points and creates a uniform surface that forklifts can travel across safely. It also helps reduce vibration and improve operator comfort.

We often combine grinding with mudjacking when the warehouse has a mix of dips and raised edges. The combination produces a level surface that performs well under constant forklift use.

Finally, if your warehouse floor is starting to sink, crack, or create problems for your forklifts, reach out to us. We have been repairing concrete warehouse floors across New Jersey and Eastern Pennsylvania for more than 20 years, and we understand exactly what it takes to restore a safe, level, and reliable surface. Our team is local, experienced, and trusted by facility managers throughout the region. Contact us today and let us help you fix your floor before the damage grows.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025