IN THIS ARTICLE

In many facilities, forklifts and pallet jacks play a crucial role in the smooth operation of the operations. To ensure that forklifts work effectively, it is essential to consider how they interact with other elements of the facility. One important aspect that is often overlooked is the condition of the concrete slabs and facility’s flooring.

Damaged floors can cause unexpected damage to equipment and products, as well as pose a safety hazard to personnel. For instance, forklifts with cushion tires are not designed to handle uneven terrain, such as floors with missing chunks or rough patches. Continuously driving on such floors can increase the frequency of tire replacement and cause strain on the forklift, affecting the budget.

In addition, damaged floors can be hazardous for the products being moved. Driving over damaged floors can cause vibrations that can damage certain types of materials. It can also increase the risk of product spills if items fall from pallets due to traveling over the uneven terrain. Concrete spalling repair can address concrete floor surface issues.

Moreover, damaged floors can place stress and strain on operators’ bodies, especially if they are driving forklifts that lack a proper suspension system. Therefore, maintaining regular floor inspections and reporting any damage to operators is essential in preventing damage and ensuring safe working conditions.

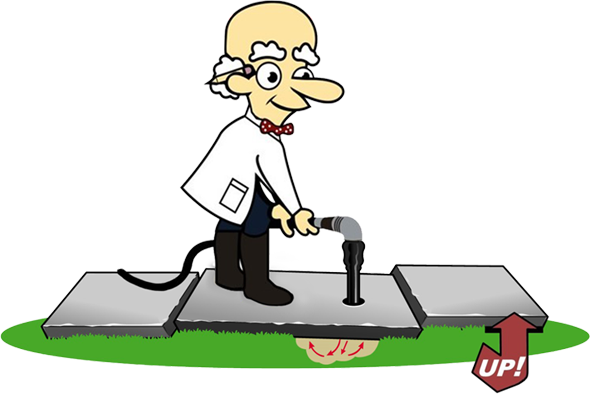

One particular area that requires frequent inspection is the joints between concrete slabs. These are likely to be the first places that fall into disrepair from natural wear and tear. Replacing damaged concrete joints might seem like a costly investment, but concrete warehouse floor joint repair can save on forklift repair costs and improve operations efficiency in the long run. Finally, it is crucial to consider how a smooth concrete floor surface plays a role in several critical forklift functions.

Uneven, cracked, or damaged concrete floors affect a forklift’s ability to stop or accelerate effectively, which can be a safety hazard. Therefore, ensuring that concrete floors in your facility remain clean, flat, and free of debris is essential to avoid potentially unsafe driving situations. In summary, having an inspection plan for concrete crack repair is critical to maintaining the optimal condition of facility floors. Material handling investments work hand in hand with facility investments from the ground up.

The Cost of Doing Nothing

The cost of neglecting repairs to warehouse floors can be substantial, impacting various aspects of operations and potentially leading to more significant expenses in the long run. While it might seem like a cost-saving strategy in the short term, the consequences of inaction can manifest in several areas, affecting safety, productivity, equipment maintenance, and overall operational efficiency.

- Safety Hazards: Unaddressed issues with warehouse floors, such as cracks, uneven surfaces, or potholes, pose significant safety risks. These hazards can result in trips, slips, and falls for both employees and visitors. Workplace accidents not only lead to potential injuries but also result in increased workers’ compensation claims and, in severe cases, legal liabilities. The cost of medical expenses, insurance premiums, and potential legal fees can far exceed the expenses associated with proactive floor repairs.

- Equipment Damage: Warehouse operations often involve the use of heavy machinery, such as forklifts and pallet jacks. Uneven or damaged floors can accelerate wear and tear on equipment, leading to more frequent breakdowns and increased maintenance costs. Forklifts, for example, may experience premature tire wear, suspension damage, and other issues when operating on poorly maintained floors. The cost of repairing or replacing equipment due to floor-related damage can be significant.

- Productivity Loss: Uneven or damaged floors can impede the smooth movement of materials and equipment within the warehouse. This can result in slower operational processes, reduced efficiency, and overall productivity losses. Delays in material handling and order fulfillment can lead to missed deadlines, customer dissatisfaction, and, in turn, potential revenue losses.

- Inventory Damage: Instability caused by uneven floors can lead to damage to stored goods and inventory. Vibrations and shocks transmitted through the floor can impact the integrity of packaged items, especially those sensitive to movement or compression. The cost of replacing damaged inventory, as well as potential losses due to customer refunds or order cancellations, adds to the overall financial impact.

- Operational Disruptions: In extreme cases, severe floor damage may force temporary shutdowns or limit access to certain areas of the warehouse. These disruptions can result in downtime, missed production targets, and a negative impact on customer service. The costs associated with interrupted operations, including overtime pay for catch-up work, can quickly escalate.

- Long-Term Repair Expenses: Ignoring minor floor issues can lead to more extensive damage over time. What might have been a relatively simple and cost-effective repair can evolve into a complex and expensive reconstruction project. Timely maintenance and repairs can prevent the escalation of problems, saving money in the long run.

In summary, the cost of doing nothing to repair warehouse floors extends beyond the immediate financial investment required for repairs. It encompasses the potential expenses associated with safety incidents, equipment damage, productivity losses, inventory damage, operational disruptions, and the eventual need for more extensive and costly repairs.

Investing in proactive warehouse floor repair is a strategic decision that not only preserves the integrity of the warehouse environment but also safeguards against escalating costs and potential legal consequences. If you are in our NJ and PA concrete warehouse floor service area, contact Concrete Chiropractor® for a professional assessment.

- Warehouse Concrete Floor Cleaning Tips: Dos and Don’ts - June 23, 2025

- How to Choose the Right Industrial Sweeper for Your Warehouse Concrete Floor - June 23, 2025

- Six Common Causes of Warehouse Concrete Floor Joint Damage - May 10, 2025