IN THIS ARTICLE

Learn Warehouse Concrete Floor Cleaning and Maintenance Tips: What you need to do or avoid for a lasting concrete floor.

If you manage or own a warehouse, you already know how much wear and tear your concrete floors take. Forklifts roll across them every day. Workers move pallets, boxes, and heavy equipment. And all that movement creates dirt, dust, and spills that need regular cleaning.

Now, we do not clean warehouse floors. We repair them. We work with concrete warehouse floors all over New Jersey—in cities like Newark, Paterson, Elizabeth, and Jersey City. We fix cracks, chips, and worn-out surfaces.

So why are we writing a blog post about cleaning?

Because how you clean your floor affects how long it lasts.

We’ve seen perfectly good floors get damaged just because someone used the wrong cleaning method or machine. So this blog isn’t about selling cleaning services. It’s about helping you avoid damage and save money on future repairs.

Let’s talk about what to do—and what not to do—when cleaning your warehouse concrete floor.

Why Cleaning Matters for Concrete Floors

Your concrete floor might look strong, but it needs care. Dirt and dust don’t just sit there. They act like sandpaper. Every time a forklift rolls over them, that grit grinds away at your floor’s surface. Over time, this wears down the finish and leads to damage.

Oil spills or chemical leaks can also break down the surface. They weaken the concrete or its coating. If not cleaned properly, they seep into small cracks and make the damage worse.

When you clean the right way, you remove those harmful materials. You help the floor last longer.

You also make the warehouse safer for your workers.

But cleaning the wrong way?

That causes more harm than good.

Cleaning Dos: Best Practices for Warehouse Concrete Floors

Let’s go over what you should do.

Sweep Regularly

Sweeping should be part of your daily or weekly routine. Even if the floor looks clean, dust and grit build up fast. Regular sweeping removes the particles that wear down your floor.

Use a soft or medium brush that won’t scratch the surface. Automatic sweepers work well if you have a large space. But even a basic push broom helps more than you think.

Use the Right Brush Type

Concrete may seem tough, but it can still get scratched. Don’t use metal brushes or very stiff bristles unless the floor is extremely dirty. Softer brushes protect the surface while still doing the job.

Clean Spills Immediately

Oil, grease, and chemical spills are a big problem for concrete. If you let them sit, they can soak into the floor and cause stains or even damage the concrete itself.

Use a neutral cleaner and a mop or scrubber. Don’t let the spill spread. Act fast.

Dry the Floor After Washing

After using water or cleaning solution, dry the floor. Standing water can find its way into joints and cracks. In cold New Jersey winters, that water freezes and expands—causing more cracks.

Use a squeegee or a wet-dry vacuum to remove extra water. Don’t leave the floor soaked.

Check the Floor While Cleaning

Use cleaning time as inspection time. Look for:

- Hairline cracks

- Uneven spots

- Loose edges around joints

- Chips near dock doors

Finding these early helps you stop bigger problems. If you spot damage, call a repair expert before it gets worse.

Cleaning Don’ts: What to Avoid

Now let’s look at what not to do. These are mistakes We see all the time. They cause real damage.

Use Harsh Chemicals

Strong acids or alkaline cleaners might work fast, but they’re too rough on concrete. They break down surface coatings and weaken the concrete itself.

Use neutral or pH-balanced cleaners if needed. Or just clean with water and a soft scrubber. You don’t need heavy chemicals for most jobs.

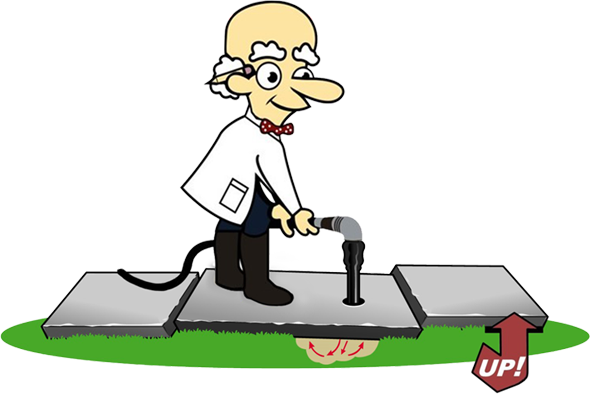

Use Too Much Water

Flooding the floor may feel like a deep clean, but it’s risky. Concrete is porous. Water can seep into the surface and joints. If your floor already has small cracks, water makes them worse.

Use only the amount of water needed to clean, and dry it up right after.

Ignore Small Cracks

When you clean, you might notice a small crack and think, “That’s nothing.” But over time, small cracks turn into big ones. Dirt and water collect inside. Every sweep or scrub makes it worse.

Make it a habit to mark or report any new cracks you see while cleaning. Don’t wait.

Drag Pallets or Carts While Cleaning

Some workers think it’s fine to push a pallet across the floor during cleaning. It’s not. Dragging heavy loads across wet or dusty concrete scratches the surface and causes wear patterns.

Always lift or roll—don’t drag.

Use Outdoor Equipment Indoors

Outdoor sweepers or scrubbers are too rough for indoor concrete. They have harder brushes and more aggressive power. Using them inside can scratch sealed floors and damage joint lines.

Choose indoor-safe tools for indoor cleaning.

Seasonal Cleaning Tips for New Jersey Warehouses

Weather affects your floor, too. If you’re in New Jersey, you see all four seasons. Each one brings its own cleaning challenge.

Winter:

- Salt from roads and shoes can break down concrete.

- Snow melt leaves water puddles. That water freezes and expands, cracking the floor.

- Sweep more often and dry floors quickly.

Summer:

- Dry weather brings more dust.

- Sweep daily to keep dust from becoming airborne.

Fall and Spring:

- Leaves and rain get tracked inside.

- Use mats near doors and keep walkways clean.

Signs It’s Time to Call for Repairs

Even with the best cleaning routine, damage can still happen. Here are signs your floor may need help:

- Cracks that grow over time

- Spots where dust keeps returning (may mean crumbling surface)

- Potholes or surface pits

- Water pooling in dips or corners

- Loose or crumbling edges near joints

If you see any of these, call a repair expert. That’s what we do. We can come check your floor and tell you if repairs are needed.

Don’t wait until the damage is big. Small repairs cost less and last longer.

You Don’t Need Fancy Cleaning Tools

Many warehouse owners think they need expensive machines. You don’t. You just need to clean the right way.

Even a push broom and mop can protect your floor if used properly. The key is to be gentle and consistent. And to fix problems as soon as they appear.

Final Thoughts

We don’t clean warehouse floors. But we fix them. We’ve seen good floors ruined by bad cleaning, and We’ve seen older floors stay strong because someone took care of them.

If you take anything from this post, let it be this: How you clean your concrete floor matters. Clean smart.

Don’t overdo it.

Use the right tools. And fix small problems before they become big ones.

If your warehouse is in New Jersey and your concrete floor needs help, reach out. Whether you’re in Newark, Paterson, Elizabeth, Jersey City, or anywhere nearby, We can take a look and give you honest advice.

We are here to help you keep your floor strong, so it lasts for years to come.

Need a floor check-up? Just call.

Let’s keep your NJ warehouse floor in good shape.

FAQs

What cleaning methods can damage a warehouse concrete floor?

Using harsh chemicals, too much water, stiff brushes, or outdoor sweepers indoors can damage concrete. These methods wear down coatings, expose the surface, or push water into cracks.

Can cleaning prevent warehouse floor cracks?

Yes, regular and proper cleaning helps prevent cracks by removing debris and moisture that weaken the concrete over time. But if cracks already exist, cleaning alone won’t fix them—you’ll need repairs.

What are the signs of damage during concrete floor cleaning?

Look out for hairline cracks, surface dust that keeps coming back, loose joint edges, or water pooling in low spots. These are early signs that your warehouse floor may need repair.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025