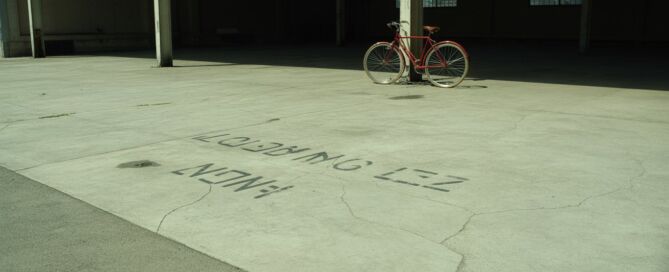

Six Common Causes of Warehouse Concrete Floor Joint Damage

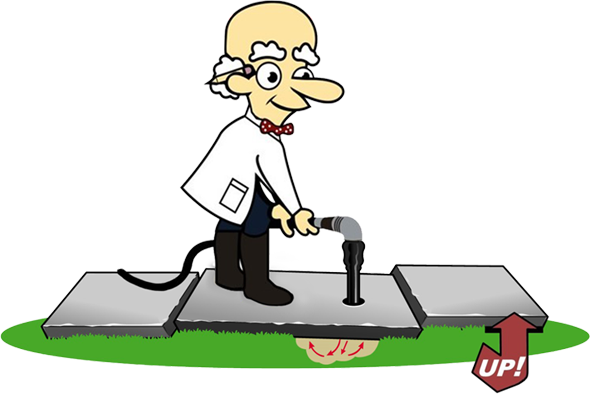

Discover The Root Causes Of Damage To Concrete Floor Joints in Warehouses Understanding what causes damage to concrete floor joints is essential for maintaining warehouse efficiency and safety. By knowing these root causes, you can [...]