IN THIS ARTICLE

Discover Why Professional Warehouse Concrete Floor Repair Pays Off

Concrete floors are the backbone of warehouse operations. Every pallet moved, every forklift pass, every rack system installed depends on the strength and condition of the floor beneath it. When warehouse concrete floors are properly maintained, they quietly support daily operations without drawing attention. When they are neglected, however, the problems show up fast, and the costs can escalate even faster.

We work exclusively on warehouse concrete floors across New Jersey and Eastern Pennsylvania, including the Lehigh Valley, Northampton, Lehigh, Bucks, Montgomery, and Philadelphia counties. Over the years, we have seen firsthand how small, ignored issues turn into major disruptions. Cracks widen. Joints break down. Uneven slabs damage equipment. Safety risks increase. What could have been a straightforward repair becomes a costly and urgent problem.

This article explains the true cost of neglecting warehouse concrete floor repairs, why professional repair pays off in the long run, and how proactive maintenance protects your operation, your people, and your property value.

The Critical Role of Concrete Floors in Warehouse Operations

Warehouse floors do far more than provide a flat surface. They support the entire operation. From heavy racking systems to constant forklift traffic, concrete floors are under stress every day.

A typical warehouse floor must handle:

- Continuous movement of forklifts and pallet jacks

- Concentrated point loads from storage racks

- Impact from dropped pallets and materials

- Abrasion from tires, wheels, and foot traffic

- Exposure to moisture, chemicals, and temperature changes

Concrete is strong, but it is not immune to wear. Over time, even well-built slabs develop cracks, surface spalling, joint deterioration, and settlement. These issues are normal, but ignoring them is where the trouble starts.

When floors remain smooth, level, and structurally sound, warehouse operations stay efficient. When floors degrade, productivity drops, equipment suffers, and safety risks increase. The floor becomes an obstacle instead of a support system.

How Minor Concrete Damage Turns Into Major Problems

One of the biggest misconceptions we hear is that small cracks or surface defects are not urgent. In reality, minor concrete damage rarely stays minor.

Cracks Grow and Spread

Concrete cracks for many reasons, including shrinkage, thermal movement, heavy loads, and subgrade issues. A hairline crack today can widen over time, especially under constant forklift traffic. Once a crack opens, it allows water, dirt, and chemicals to penetrate deeper into the slab.

This internal damage accelerates deterioration and can eventually compromise the structural integrity of the floor.

Joint Failure Leads to Uneven Surfaces

Control joints are designed to manage concrete movement. When joints are not properly maintained, their edges can chip and break down. This creates uneven transitions that forklift wheels hit thousands of times a day.

Over time, joint deterioration causes faulting, where one side of the slab becomes higher than the other. This not only damages equipment but also increases safety hazards for workers.

Surface Spalling Gets Worse With Traffic

Spalling occurs when the surface layer of concrete flakes or breaks away. This often starts small, but once the surface is compromised, abrasion and impact accelerate the damage.

Ignoring spalling leads to rough, uneven floors that are harder to clean, more dangerous to walk on, and more expensive to repair later.

The Financial Cost of Ignoring Warehouse Floor Repairs

Neglecting warehouse concrete floor repairs almost always costs more in the long run. The expenses may not show up immediately, but they add up quickly.

Escalating Repair Costs

Early-stage repairs are usually targeted and cost-effective. Crack injection, joint repair, or surface patching can address issues before they spread. When damage is ignored, the repair scope increases.

What could have been a localized repair may require:

- Large-scale slab grinding or leveling

- Extensive joint reconstruction

- Partial slab replacement

- Extended downtime during repairs

Emergency repairs also tend to be more expensive. When floors fail unexpectedly, repairs must happen quickly, often disrupting operations and increasing labor costs.

Downtime and Lost Productivity

Damaged floors often force warehouse managers to block off affected areas. This reduces usable space and slows workflow. Forklifts may need to reroute. Storage layouts may need temporary changes. Employees work more cautiously, reducing efficiency.

Even small slowdowns, when multiplied across shifts and weeks, translate into real financial losses.

Equipment Damage and Maintenance Costs

Forklifts, pallet jacks, and automated equipment are designed to operate on smooth, level surfaces. Uneven floors, broken joints, and spalled concrete place additional stress on wheels, axles, bearings, and frames.

Over time, this leads to:

- More frequent equipment repairs

- Shortened equipment lifespan

- Unexpected breakdowns that disrupt operations

The cost of repairing or replacing warehouse equipment often exceeds the cost of timely floor repairs.

Property Value and Leasing Impacts

For building owners, neglected concrete floors can directly affect property value. Warehouses with visible floor damage are less attractive to potential tenants and buyers. Leasing negotiations become harder, vacancy periods increase, and property appraisals may suffer.

For tenants, poorly maintained floors can strain landlord relationships and complicate lease renewals.

Operational Disruptions Caused by Poor Floor Conditions

Warehouse efficiency depends on smooth movement. When floors are compromised, operations feel it immediately.

Slower Material Handling

Forklift operators naturally slow down when navigating uneven floors. Sharp joint edges and cracked surfaces force cautious driving to avoid equipment damage or load instability. This reduces throughput and increases cycle times.

Reduced Storage Efficiency

Uneven floors can affect racking systems. If slabs settle or joints fail, rack alignment can be compromised. This increases the risk of instability and limits how safely loads can be stacked.

Cleaning and Maintenance Challenges

Damaged floors are harder to clean. Cracks and spalled areas trap dirt, dust, and moisture. This can create hygiene issues, especially in food, pharmaceutical, or distribution facilities with strict cleanliness standards.

Safety Risks and Liability Concerns

Warehouse safety is directly tied to floor conditions. Neglecting concrete repairs increases the risk of accidents and legal exposure.

Slip, Trip, and Fall Hazards

Cracks, uneven slabs, and broken joints create trip hazards for employees and visitors. Slip and fall injuries are among the most common workplace incidents and often result in lost workdays, workers’ compensation claims, and higher insurance premiums.

Even a single serious injury can have long-lasting financial and operational consequences.

Forklift and Vehicle Accidents

Uneven floors increase the risk of forklift instability, especially when carrying elevated loads. Sudden jolts caused by damaged joints or spalled areas can cause loads to shift or fall, putting operators and nearby workers at risk.

Regulatory and Compliance Issues

Warehouse facilities are expected to maintain safe working conditions. Inspectors may cite damaged floors as safety violations. In some cases, severe conditions can lead to fines or mandated repairs under tight deadlines.

Tenant and Owner Liability

Depending on lease terms, responsibility for floor maintenance may fall on tenants, owners, or both. When accidents occur, failure to address known floor issues can increase liability exposure.

Long-Term Structural and Environmental Consequences

Beyond immediate safety and operational concerns, neglected concrete floors can cause deeper structural and environmental issues.

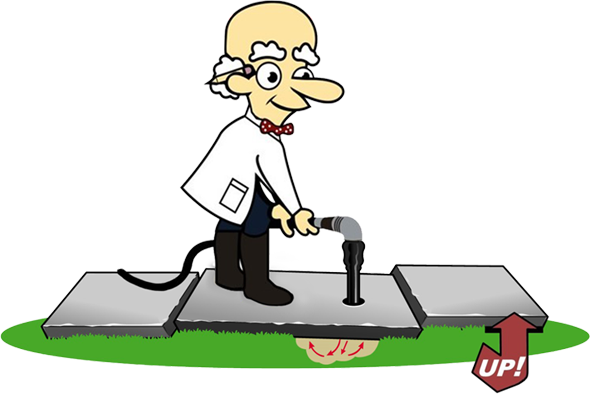

Water Intrusion and Subgrade Damage

Cracks and open joints allow water to penetrate the slab. Over time, this moisture can weaken the subgrade beneath the concrete. As the supporting soil erodes or compresses, slabs may settle or sink, creating uneven floors and additional cracking.

Reinforcement Corrosion

In reinforced concrete slabs, moisture intrusion can reach the steel reinforcement. When steel corrodes, it expands, causing internal pressure that leads to cracking and spalling. This type of damage is costly to repair and often requires more invasive methods.

Mold and Indoor Air Quality Concerns

Persistent moisture problems can contribute to mold growth in and around floor systems. Poor indoor air quality affects employee health and can create compliance challenges, especially in regulated industries.

Why Professional Warehouse Concrete Floor Repair Makes Sense

Professional warehouse concrete floor repair is not just about fixing visible damage. It is about addressing root causes and extending the life of your floor.

Accurate Assessment and Targeted Solutions

Professional contractors evaluate the type, cause, and severity of floor damage. This ensures repairs are appropriate and effective. Treating symptoms without addressing underlying issues often leads to repeat failures.

Proper Materials and Methods

Warehouse floors require industrial-grade repair materials designed to handle heavy loads and constant traffic. Professional repairs use products and techniques suited for high-demand environments, not temporary fixes.

Minimal Disruption to Operations

Experienced warehouse floor repair teams understand the importance of keeping operations running. Repairs can often be phased or scheduled to minimize downtime and disruption.

Long Term Cost Savings

Addressing issues early extends the lifespan of the floor and reduces the need for large scale repairs or replacement. Over time, this approach saves money and protects your investment.

Serving New Jersey and Eastern Pennsylvania Warehouse Facilities

We focus exclusively on warehouse concrete floor repair. We do not work on residential floors, decorative concrete, or unrelated surfaces. Our work is dedicated to industrial and warehouse environments, where performance, safety, and durability are paramount.

We proudly serve warehouse facilities across:

- New Jersey

- Eastern Pennsylvania

- Lehigh Valley

- Northampton County

- Lehigh County

- Bucks County

- Montgomery County

- Philadelphia County

Because we work in these areas every day, we understand the regional conditions, soil characteristics, and operational demands common to local warehouses.

Invest in Your Floor Before Neglect Costs You More

Neglecting warehouse concrete floor repairs may seem like a way to save money, but it almost always leads to higher costs, increased risk, and operational headaches. Small issues grow. Equipment suffers. Safety incidents become more likely. Productivity drops.

Professional warehouse concrete floor repair is not an expense. It is an investment in safety, efficiency, and long-term performance.

If you manage or own a warehouse in New Jersey or eastern Pennsylvania and are noticing cracks, uneven areas, joint damage, or surface wear, now is the time to take action.

We specialize in repairing warehouse concrete floors throughout New Jersey and the eastern part of Pennsylvania, including the Lehigh Valley, Northampton, Lehigh, Bucks, Montgomery, and Philadelphia counties.

Contact us to schedule a professional evaluation. We will help you understand the condition of your floor, explain your repair options clearly, and recommend practical solutions that fit your operation. Taking action now can save you time, money, and disruption down the road.

- Will You Lose Your Deposit Over Warehouse Concrete Floor Cracks? - December 19, 2025

- Who Pays for Warehouse Concrete Floor Repairs in a Lease – Tenant or Landlord? - December 19, 2025

- Can You Fix Concrete Floor Gouges Yourself? - December 19, 2025